- Joined

- Jun 20, 2022

- Messages

- 235

But managed to save it.

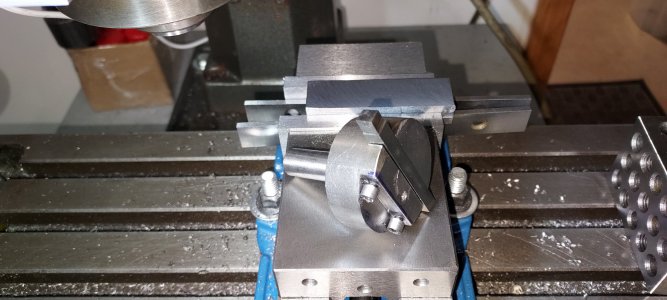

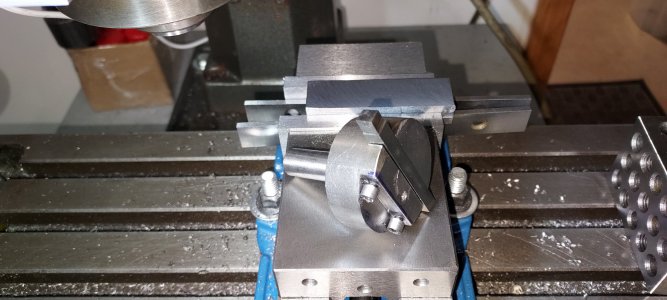

Metal supplier was late, so decided my first project on the new to me milling machine would be with what's on hand.

Found some 1.75" round cast iron, and 1/2" drill rod. Figured a fly cutter was in there somewhere.

All was going according to plan until boring the arbor hole. I won't go into detail but my boring bar was rubbing and opened that cast iron up to several thou bigger than 1/2"

I figured concentricity isn't of the utmost in a flycutter so pressed on. Epoxy the arbor into the body. The drill and tap it for what I think is called a "scotch pin"(?). You can see the offset hole that bisects both parts. Seems to hold and work fine, despite the mistake.

Metal supplier was late, so decided my first project on the new to me milling machine would be with what's on hand.

Found some 1.75" round cast iron, and 1/2" drill rod. Figured a fly cutter was in there somewhere.

All was going according to plan until boring the arbor hole. I won't go into detail but my boring bar was rubbing and opened that cast iron up to several thou bigger than 1/2"

I figured concentricity isn't of the utmost in a flycutter so pressed on. Epoxy the arbor into the body. The drill and tap it for what I think is called a "scotch pin"(?). You can see the offset hole that bisects both parts. Seems to hold and work fine, despite the mistake.