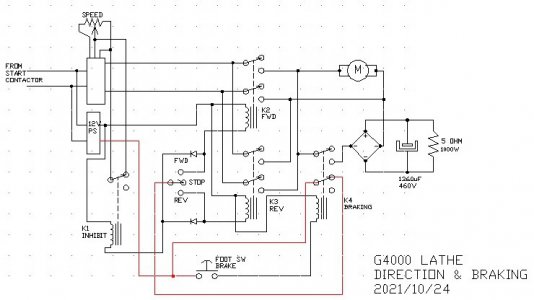

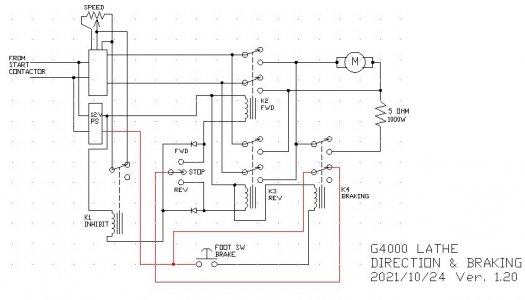

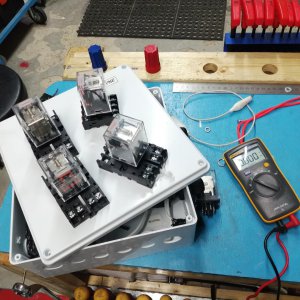

....and this is what I have on the drawing-board for the new direction and braking system after the ELS is implemented. The speed controller is already there (16 years), the direction switching is pretty straightforward and is a mod of the existing, and a mock-up of the foot-brake system proves successful. Essentially, for braking, we're removing power from the motor and shunting the motor with a massive RC network, dumping the back EMF of the motor into the load (regenerative braking).

View attachment 382994

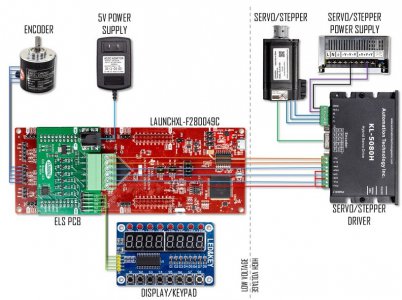

It looks like you have a great start on the ELS.

Re: the brake, a coupl3e of points. It appears that you have a bridge rectifier to handle the fwd/rev situation so the capacitor always see the correct polarity. The capacitor will essentially be a dead short when the brake circuit is energized. As such the circuit can experience transient currents into the thousands of ohms which can destroy the bridge rectifier. You will also create a large amount of EMF which could interfere with the ELS. On a conversion of my lather to a dc PWM driven motor, I was destroying MOSFET transistors rated at 500 amps pulsed until I realized that I had to add a transient snubber to the motor. I have a 3,000 mfd filter in my power supply, directly connected to the bridge rectifier and I was destroying switch contacts until I added a inrush current limiter to the circuit.

But the question that I have is why bother with the capacitor and bridge at all? The capacitor will quickly discharge to zero volts after initial contact is made and really serve no useful purpose. The resistor alone will do the job. Transient current will be limited to a few tens of amps which will be easier on your relay contacts and reduce EMF.

As to the wattage of the resistor, the duty cycle of the brake will be minimal so a 1000 watts is overkill. You could do a calculation of the required wattage by assuming the the entire kinetic energy of the motor, spindle assembly, and work was being absorbed by the resistor and making a guess as to mass and its distribution and the maximum rpm. I did a rough calculation assuming 2,000 rpm and a mass of 20 kg located on a rim 4 cm in radius and calculated about 2,000 joules of energy. A 50 watt resistor can safely dissipate 3,000 joules/min so a start /stop every 40 seconds would be permitted. This should be a very conservative estimate.

I would venture to say that unless you were starting and stopping multiple times a minute, a 50 watt resistor with proper heat sinking would suffice. Of course, if you already have a water heater element and you have the room to install it, why not?