I haven't actually hooked up the oil pump, but the system went together fairly easily, based on Hoss' Phase 3 plans.

I'm not sure why X would be the problem. I did have to mill away some of the slide to allow the right angle fitting to sit in there, but that's in Hoss' videos on the DVD.

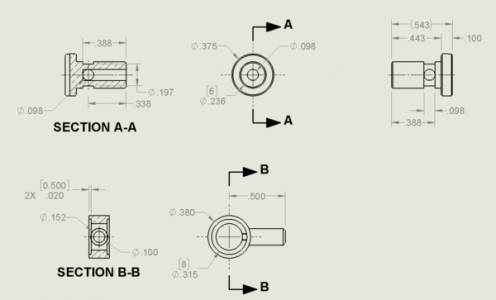

View attachment 228859

The one I had problems with was Y and I had to grind back the slide with an angle grinder. Hoss just bent down the tubing and (I guess) let the cross slide slide across that tube. I have a build thread where I showed what I went through (actually, someone else started it and I ended up hijacking the thread when he stopped posting). The Y-axis oiling starts

here. If that doesn't work, the first page is here, and just got to page 5, you'll find it.

From what I've read about that question of dripping oil on the ballscrew, the Teflon (? I think) seals at the front and back of the ballnut wipe the oil off. You don't get oil onto the balls and threads inside it. I'm trying to find some oil to use in the system today.

Like a lot of people, I haven't finished the Z-axis. It turns out Hoss never finished it, either, which I only found by asking him on the CNCZone forum. When I was building up the Z-axis, I found the right angle fitting didn't fit inside the Z column. I never came up with a good answer to that.