- Joined

- Feb 17, 2013

- Messages

- 4,417

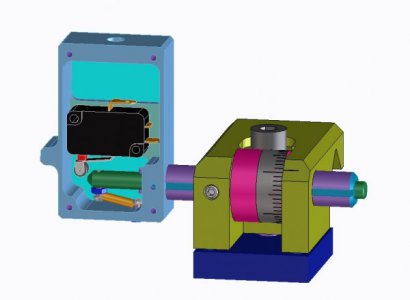

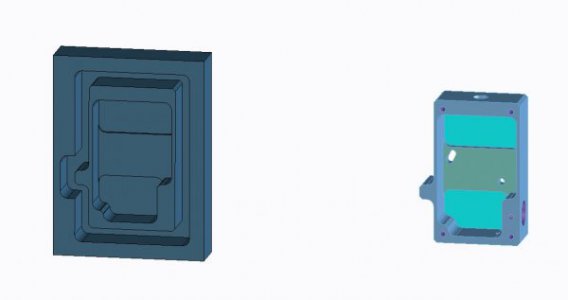

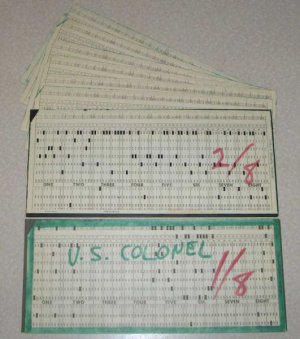

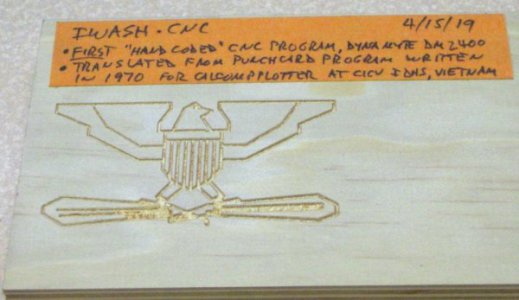

I recently bought a vintage DynaMyte DM2400 mill, converted to Centroid CNC, as a way of "taking the plunge" into CNC. I also bought Fusion 360, because my previous CAD software (CREO Elements Direct, free/restricted version) couldn't output any appropriate format. I've finally learned enough Fusion to design a CNC-ble part and used the Manufacture tab to produce tool paths. But I've run into some extremely irritating bugs, and wonder if anybody else has seen these and knows how to address them:

1. The G-code that Fusion outputs includes several instructions that have a colon ( : ) in them. Centroid does not recognize the colon as a valid character, and pukes out an error message. I've tried to search G-code reference info, but can't find any definition of the colon character.

2. For radial moves (G17), Fusion designates the radius with a P instead of the R specified by G-code. Again, Centroid pukes, and I have to go back in and do a universal find-and-replace to fix the code.

3. The alternate way to designate G17/18/19 moves is by using I and J. Unfortunately, Fusion uses absolute position values, while Centroid (as set up when I bought the mill) is set up to use relative I and J values. VERY interesting results! The tool paths I get when graphing with Centroid have lots of HUGE loop-de-loops. I think I know how to set the correct bit in Centroid to change to absolute I,J. But I was wondering if there's a way to tell Fusion to use relative values.

4. Following every tool change, Fusion output includes an H0 (ignore tooling height offsets), rather than the H1, H2, etc. that (I think) it should be using.

Thanks for any help!

1. The G-code that Fusion outputs includes several instructions that have a colon ( : ) in them. Centroid does not recognize the colon as a valid character, and pukes out an error message. I've tried to search G-code reference info, but can't find any definition of the colon character.

2. For radial moves (G17), Fusion designates the radius with a P instead of the R specified by G-code. Again, Centroid pukes, and I have to go back in and do a universal find-and-replace to fix the code.

3. The alternate way to designate G17/18/19 moves is by using I and J. Unfortunately, Fusion uses absolute position values, while Centroid (as set up when I bought the mill) is set up to use relative I and J values. VERY interesting results! The tool paths I get when graphing with Centroid have lots of HUGE loop-de-loops. I think I know how to set the correct bit in Centroid to change to absolute I,J. But I was wondering if there's a way to tell Fusion to use relative values.

4. Following every tool change, Fusion output includes an H0 (ignore tooling height offsets), rather than the H1, H2, etc. that (I think) it should be using.

Thanks for any help!

Last edited: