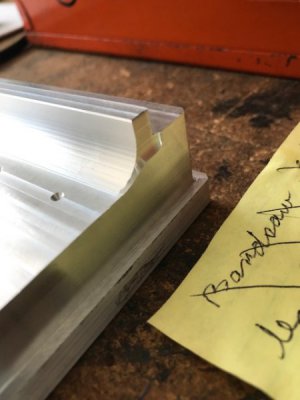

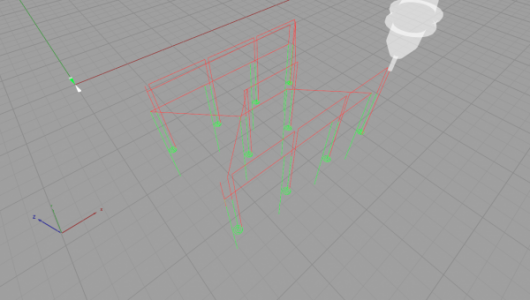

After modeling an aluminum part using Fusion 360 I set up the machining operations using the built in CAM package. It all looked good running in simulation but the final outcome was not right. The machining origin is the top/left corner. As I went through each operation I checked for size and hole placement. Everything was good until the last two operations. You will notice the difference in wall thickness on the pocket outer edges and the counterbores are not lined up with the holes. I double checked my model and it does not reflect these offsets. Checked my machining origin and it was at 0,0. Anyone else have issues with Fusion 360 CAM not generating an accurate tool path?