- Joined

- Oct 7, 2020

- Messages

- 2,347

So, I decided to try my luck at internal threading. I had never used my boring bar before either and failed at hitting my numbers. I'm not sure what happened but I'm thinking I must have read my snap gauge wrong or didn't take a good reading with it. At any rate after drilling and the first couple of bores I read .802 took .020 ended up with .824, took .023 measured .850, took .048 measured .900, took .050 measured .983 WTH . I was shooting for .9515. Oh well it was on a test piece anyway. I went ahead and threaded it just like I was threading 1" x 20. My very first run at it I crashed my cutter into the end of the bore.  I had it bored to 1.25" so I was planning on stopping at 1", I guess I had spindle going to fast as when I went to disengage the half nut it was stiff and took more force than I expected....... CRASH!!! Luckly no damage to cutting insert or anything else that I can tell. It did knock the tool post out of alignment other than that all seems OK.

I had it bored to 1.25" so I was planning on stopping at 1", I guess I had spindle going to fast as when I went to disengage the half nut it was stiff and took more force than I expected....... CRASH!!! Luckly no damage to cutting insert or anything else that I can tell. It did knock the tool post out of alignment other than that all seems OK.

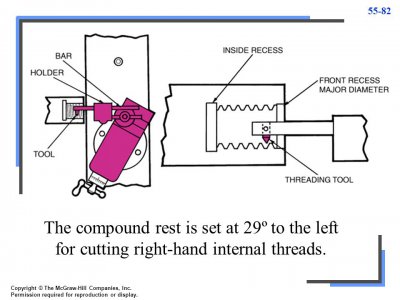

From then on all went well. I slowed the spindle down to 110 RPM and at the 1 inch mark I would turn the cross slide in and disengage the half nut, back out, zero the cross-slide dial in 5 thousand on the compound and repeat.

I had it bored to 1.25" so I was planning on stopping at 1", I guess I had spindle going to fast as when I went to disengage the half nut it was stiff and took more force than I expected....... CRASH!!! Luckly no damage to cutting insert or anything else that I can tell. It did knock the tool post out of alignment other than that all seems OK.

I had it bored to 1.25" so I was planning on stopping at 1", I guess I had spindle going to fast as when I went to disengage the half nut it was stiff and took more force than I expected....... CRASH!!! Luckly no damage to cutting insert or anything else that I can tell. It did knock the tool post out of alignment other than that all seems OK.From then on all went well. I slowed the spindle down to 110 RPM and at the 1 inch mark I would turn the cross slide in and disengage the half nut, back out, zero the cross-slide dial in 5 thousand on the compound and repeat.