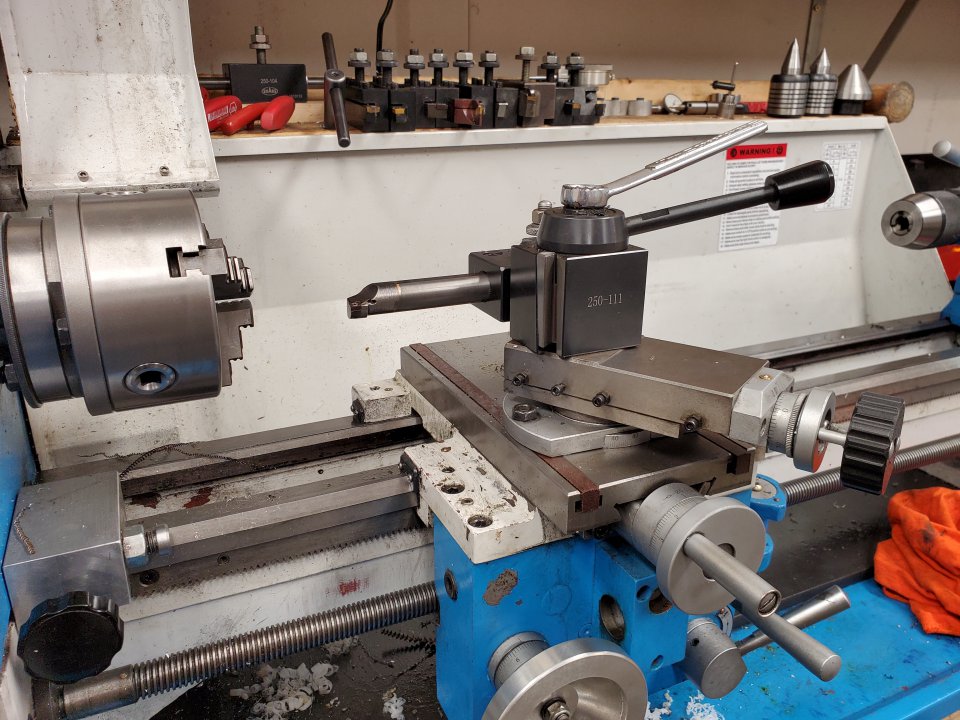

Fun little project for my PM1030V.

A while back I had to bore out a 6" deep hole and it took a bunch of stock removal. I did fine with it but I had to keep my cuts pretty small, which is fine for such a small lathe.

Today I decided I wanted to build a solid tool post for my 3/4" solid carbide boring bars.

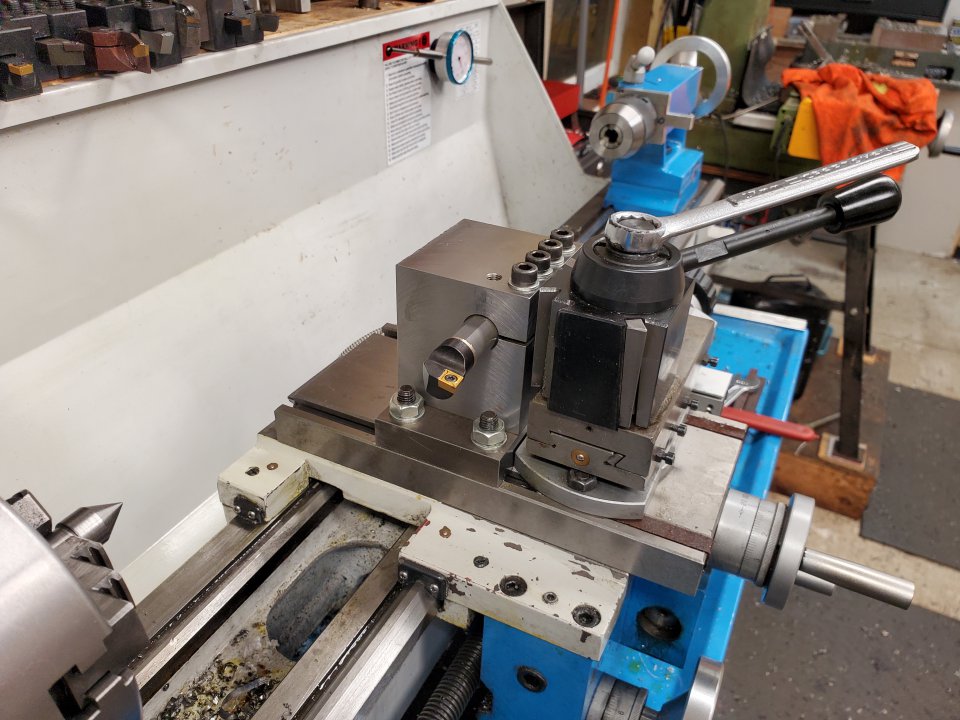

It consists of a 3/4" thick plate 3" x 5" with a 3 x 3 x 3 block of steel bolted to it. I used my lathe to drill and ream the block so it is definitely on dead center.

I put a single set screw dead center of the top of the hole simply to align the flat on the bar properly. Then I retract the set screw before tightening the clamp.

I left the cap screws on the surface without counterboring because I want the washers to take the wear instead of the bottom of the hole in the unhardened steel block. I can replace the washers as needed.

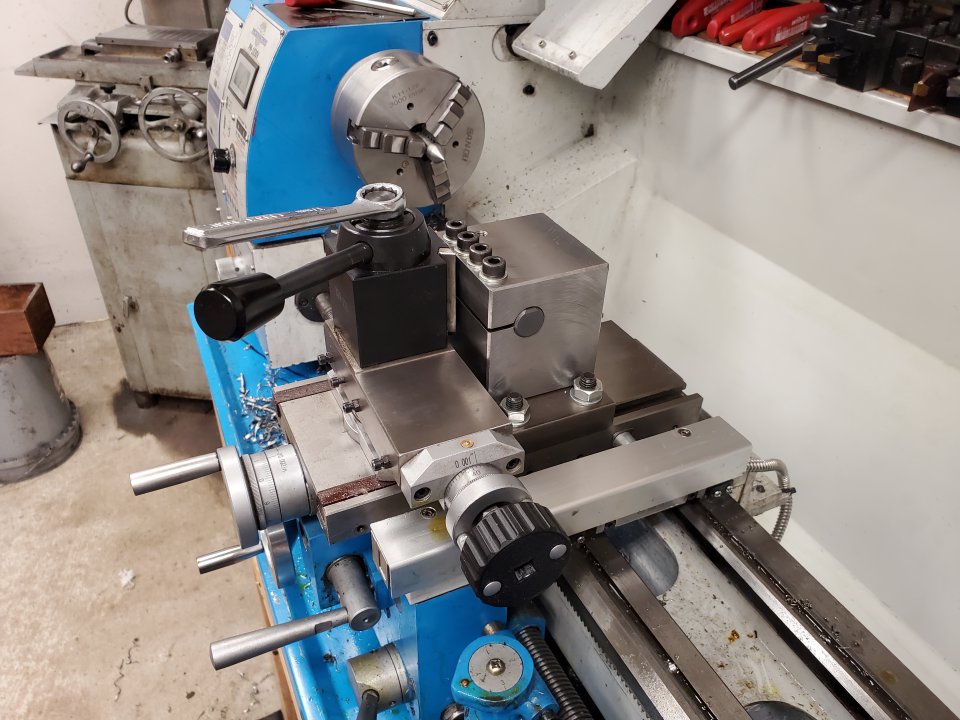

The solid tool post can bore up to 5.5" where it is now. If I remove the compound I can go all the way out. If I need to bore a big deep hole it is extremely easy to pull the compound so it's not a time waster to use the solid tool post on a big project.

I'll make a sleeve for 1/2" bars too but I don't think I'll bother with smaller bars. They do fine in the standard tool post.

Frankly I have never had rigidity issues on regular turning. I run out of power way before the cut gets too big.

A while back I had to bore out a 6" deep hole and it took a bunch of stock removal. I did fine with it but I had to keep my cuts pretty small, which is fine for such a small lathe.

Today I decided I wanted to build a solid tool post for my 3/4" solid carbide boring bars.

It consists of a 3/4" thick plate 3" x 5" with a 3 x 3 x 3 block of steel bolted to it. I used my lathe to drill and ream the block so it is definitely on dead center.

I put a single set screw dead center of the top of the hole simply to align the flat on the bar properly. Then I retract the set screw before tightening the clamp.

I left the cap screws on the surface without counterboring because I want the washers to take the wear instead of the bottom of the hole in the unhardened steel block. I can replace the washers as needed.

The solid tool post can bore up to 5.5" where it is now. If I remove the compound I can go all the way out. If I need to bore a big deep hole it is extremely easy to pull the compound so it's not a time waster to use the solid tool post on a big project.

I'll make a sleeve for 1/2" bars too but I don't think I'll bother with smaller bars. They do fine in the standard tool post.

Frankly I have never had rigidity issues on regular turning. I run out of power way before the cut gets too big.