- Joined

- Oct 28, 2020

- Messages

- 542

Hey Guys

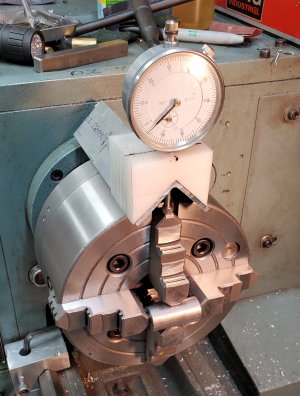

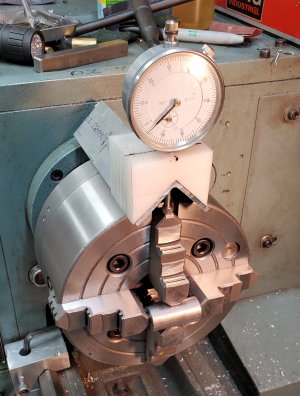

I just wanted to share an aide I made up, (threw together super quick), to help indicating in the four jaw chuck. a difficult situation comes up when trying to cross drill cylindrical parts in the four jew. (for our discussion suppose that a mill in not available ).

with a cylindrical part in the four jaw, the jaws themselves are the only place to indicate.. the traditional method is to use an arm on a magnetic base, then the plunger on the indicator is pulled up out of harms way as the next jaw is rotated under the indicator. I'm allways fearful of whacking the indicator stem with a jay as it comes around.

The situation is a pain ... so i threw together an indicator holder that can be remove completley when rotating the chuck and adjusting the jaws

the angle sits on the chuck and has a stop on the back side that rest up against the head-stock. when rotating to the next jaw the indicator and holder are simple lifted away no risk of wacking the plunger. I did a super fast throw together on the holder. the indicator is a nice tight friction fit in the UHMW. The UHMW is pop riveted to the angle. the repatability may not be aerospace rated but for my basement shop it works well. Just like the magnetic arm the "sweet" spot in the grind of the jaws must be found to get an accurate reading.

Thanks for looking.

I made a quick video on this interesting problem and solution.

I just wanted to share an aide I made up, (threw together super quick), to help indicating in the four jaw chuck. a difficult situation comes up when trying to cross drill cylindrical parts in the four jew. (for our discussion suppose that a mill in not available ).

with a cylindrical part in the four jaw, the jaws themselves are the only place to indicate.. the traditional method is to use an arm on a magnetic base, then the plunger on the indicator is pulled up out of harms way as the next jaw is rotated under the indicator. I'm allways fearful of whacking the indicator stem with a jay as it comes around.

The situation is a pain ... so i threw together an indicator holder that can be remove completley when rotating the chuck and adjusting the jaws

the angle sits on the chuck and has a stop on the back side that rest up against the head-stock. when rotating to the next jaw the indicator and holder are simple lifted away no risk of wacking the plunger. I did a super fast throw together on the holder. the indicator is a nice tight friction fit in the UHMW. The UHMW is pop riveted to the angle. the repatability may not be aerospace rated but for my basement shop it works well. Just like the magnetic arm the "sweet" spot in the grind of the jaws must be found to get an accurate reading.

Thanks for looking.

I made a quick video on this interesting problem and solution.