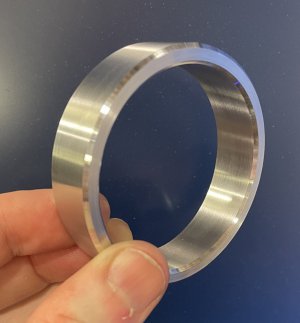

If you want to get as close to round as possible, that is a different thought pattern. To get to perfectly round you will need one whole ring per half of the finished part since each half is more that 180° of ring by the height of the hinge.

First you will want to cut it in half on the mill with a slitting saw as it will leave a nice surface finish that requires no more clean up. You can get slitting blades that are thinner than your band saw blade. I have used 0.010 thick saws cutting through a half inch of Titanium with no problem. When setting it up for flat in the mill you will want the left end set so that it is level with the center line of the hinge pin.

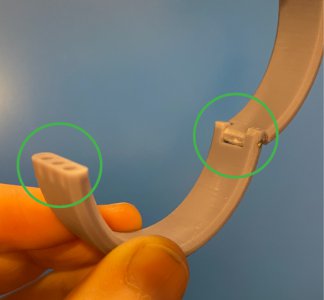

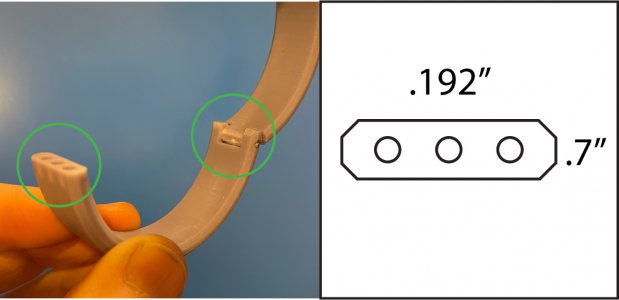

You will need to just touch the left end with a mill to make it in the same plane as the hinge pin or you will have a tapered gap of zero on the outside and a gap of, the thickness of the blade you used to make the cut, on the inside when closed.