I posted an earlier introductory post about my recent acquisition of a Langun FT-2 mill (here), where I explained that to move the mill into my space I had to remove the x-axis table. After doing that I decided to remove the y-axis as well, just to check things out.

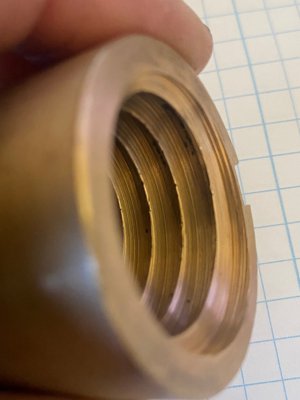

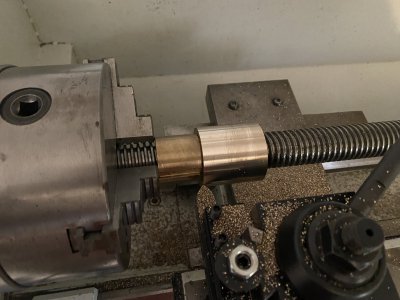

This investigation revealed two issues - one was that the lubrication pump was non-functional (I'll post separately), and the other was the discovery that the x-axis lead screw nuts (it is a split-nut pair, not a single nut) were seriously worn. The lead screw itself looked reasonable - I did a semi-quantitative inspection using an acme thread-pitch guage and I could barely notice a difference in wear comparing middle of the screw to the ends. But the leadscrews themselves were seriously worn. I didn't even bother measruing, they rattled around by hand, and the acme threads were worn pretty thin.

So I called Lagun to get a quote. 1st off they wanted to suggest I replace the screw as well as the nuts, which I understand but honestly felt the screw was servicable. But I said sure - send me a quote: $1,600. Uh - no. Send me a quote for just the nuts: $689.78. And it is a single nut - I was told that they moved from the split nut design in later years (which is interseting becasue seems to me others have gone in oposite diredtion).

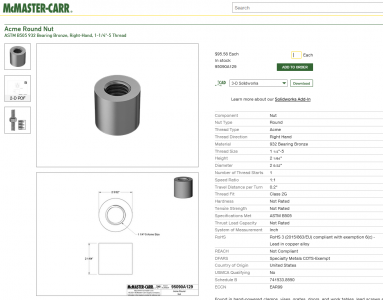

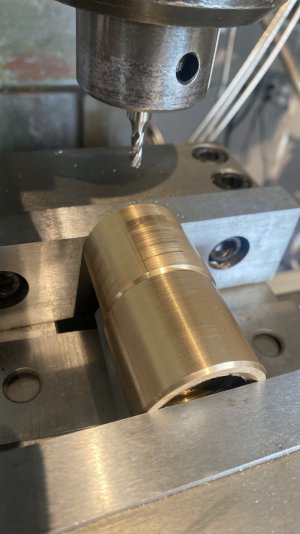

Nearly $700 for a bronze acme-thread nut? Ok - it has a keway too. But that's not going to happen. I could not find much info on this online, so I'm posting my journey on how I resolved this in case it can help others.

This investigation revealed two issues - one was that the lubrication pump was non-functional (I'll post separately), and the other was the discovery that the x-axis lead screw nuts (it is a split-nut pair, not a single nut) were seriously worn. The lead screw itself looked reasonable - I did a semi-quantitative inspection using an acme thread-pitch guage and I could barely notice a difference in wear comparing middle of the screw to the ends. But the leadscrews themselves were seriously worn. I didn't even bother measruing, they rattled around by hand, and the acme threads were worn pretty thin.

So I called Lagun to get a quote. 1st off they wanted to suggest I replace the screw as well as the nuts, which I understand but honestly felt the screw was servicable. But I said sure - send me a quote: $1,600. Uh - no. Send me a quote for just the nuts: $689.78. And it is a single nut - I was told that they moved from the split nut design in later years (which is interseting becasue seems to me others have gone in oposite diredtion).

Nearly $700 for a bronze acme-thread nut? Ok - it has a keway too. But that's not going to happen. I could not find much info on this online, so I'm posting my journey on how I resolved this in case it can help others.