- Joined

- Dec 28, 2022

- Messages

- 276

So over the past couple of days, I decided to try making a tool versus spending several hundred dollars on one with multiple bushings, etc..

Right now, I only need this for one project I want to do, so I made the dimensions for that. When I need to do this again, I will probably purchase the kit for this, and my next tool project (Also will be made for this specific item)

I made an Action Mandrel:

So, I took a 1.5' stainless shaft piece that I had gotten from the metal recycle bin at work, set my length to 12" (OAL of entire piece was about 15-16"), set up my steady rest for the first time, after getting quite a lot of chatter at the far end, and started taking off material. This was the most machining I have done yet. While it isn't "Perfect" as I am undersized by a couple thou on the shaft portion, it will work for what I need to do. The threads came out pretty much spot on, I made them a bit loose as this is really hard stainless and I don't want it to gall. Both ends are center drilled as well if I want to use between centers.

In my opinion, not bad for a self taught newbie with ZERO machining experience!! . Could be better, could be worse! It can only get better from here!!

. Could be better, could be worse! It can only get better from here!!

On to the pics!

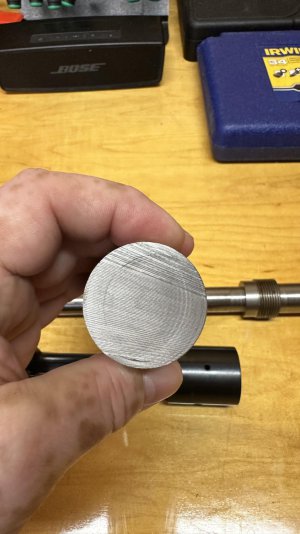

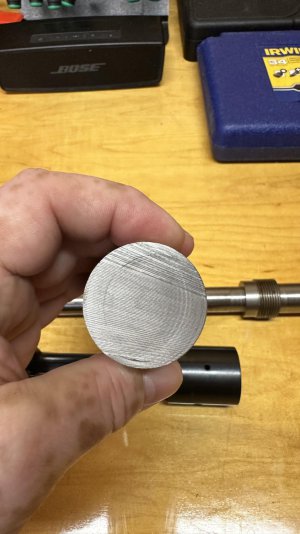

Leftover piece of original shaft

Mandrel, action and leftover piece:

Mandrel Installed:

Right now, I only need this for one project I want to do, so I made the dimensions for that. When I need to do this again, I will probably purchase the kit for this, and my next tool project (Also will be made for this specific item)

I made an Action Mandrel:

So, I took a 1.5' stainless shaft piece that I had gotten from the metal recycle bin at work, set my length to 12" (OAL of entire piece was about 15-16"), set up my steady rest for the first time, after getting quite a lot of chatter at the far end, and started taking off material. This was the most machining I have done yet. While it isn't "Perfect" as I am undersized by a couple thou on the shaft portion, it will work for what I need to do. The threads came out pretty much spot on, I made them a bit loose as this is really hard stainless and I don't want it to gall. Both ends are center drilled as well if I want to use between centers.

In my opinion, not bad for a self taught newbie with ZERO machining experience!!

On to the pics!

Leftover piece of original shaft

Mandrel, action and leftover piece:

Mandrel Installed: