- Joined

- Dec 18, 2019

- Messages

- 7,428

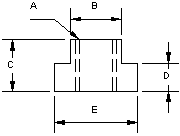

Nothing earth shattering, but a first step for me. The vise that I got with the mill had gigantic tee-bolts. The bolts were much larger than the slots. The keys for the vise are too large for my 12mm slots. Fortunately PM has slipped in some tee-bolts that would fit my machine. I used them to hold down the vise.

Apparently I was 20 minutes late for ordering a tie down kit at PM that I could use directly. They still don't have the kit in stock. However, I do have a 1/2" clamp kit that I had bought for my drill press a while ago. Decided to re-purpose the kit for the mill. So first thing to do is to mill down a couple of tee slot nuts, so I can get rid of the tee bolts.

Did a poor mans tram and decided that the existing tram was good enough for doing some tee slot nuts, hey they're not big, right? Mounted the vise and trammed it to the table. Got it to about 0.0002 over the fixed vise jaw. Not terrible for a first time at it. Had a little trouble sorting out fine feed, but kind of blundered my way through that. Milled off the edges with a coarse 4 flute end mill. Didn't try to hog anything out, just took a pass of a few thousandths to get an idea of what speeds would work. The finish was pretty nice, better than I expected. Buoyed by that success, I decided to side mill the slot width. I intended to not take off any of the underside of the tee, but took a little of the black oxide off. Guess the end mill was a tad low.

Found out why there is a need for edge finders. Despite that, things came out well enough. Took a few passes at it, and eventually I had two tee slot nuts that fit my table. They are wide enough that they scraped out some of the cosmoline I missed in the corners of the tee slots. But they do move smoothly along the slots. Eventually I'll do 6 more. They won't take very long, as I've mostly figured out what to do. After the tee slot nuts are done, I'll tackle the vise keys, that looks like an interesting minor project.

May not seem like much, but I pretty pleased with this.

Apparently I was 20 minutes late for ordering a tie down kit at PM that I could use directly. They still don't have the kit in stock. However, I do have a 1/2" clamp kit that I had bought for my drill press a while ago. Decided to re-purpose the kit for the mill. So first thing to do is to mill down a couple of tee slot nuts, so I can get rid of the tee bolts.

Did a poor mans tram and decided that the existing tram was good enough for doing some tee slot nuts, hey they're not big, right? Mounted the vise and trammed it to the table. Got it to about 0.0002 over the fixed vise jaw. Not terrible for a first time at it. Had a little trouble sorting out fine feed, but kind of blundered my way through that. Milled off the edges with a coarse 4 flute end mill. Didn't try to hog anything out, just took a pass of a few thousandths to get an idea of what speeds would work. The finish was pretty nice, better than I expected. Buoyed by that success, I decided to side mill the slot width. I intended to not take off any of the underside of the tee, but took a little of the black oxide off. Guess the end mill was a tad low.

Found out why there is a need for edge finders. Despite that, things came out well enough. Took a few passes at it, and eventually I had two tee slot nuts that fit my table. They are wide enough that they scraped out some of the cosmoline I missed in the corners of the tee slots. But they do move smoothly along the slots. Eventually I'll do 6 more. They won't take very long, as I've mostly figured out what to do. After the tee slot nuts are done, I'll tackle the vise keys, that looks like an interesting minor project.

May not seem like much, but I pretty pleased with this.