- Joined

- Aug 2, 2020

- Messages

- 683

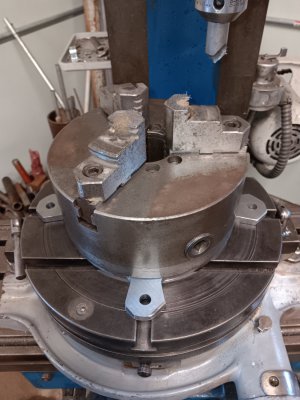

I made a plate to attach an old beater 8" 3 jaw chuck to it.

I started with a 8x8" - 3/8 thick drop from a shear and doodled my way through it.

But a shear deforms a small piece like this and it was bent and wobbly by about 8 thou.

I'll be aware of that in the future.

I brought it to a guy who has a surface grinder. Told him I don't care about the finish. Just flatten it.

It's within half a thou now.

I drilled the 4 holes 1/16" oversize so I can dial in a part in the 3 jaw then tighten the plate down.

By the way,

I'm starting to accept that I'm not a real machinist. I just make things so I can make things.

I started with a 8x8" - 3/8 thick drop from a shear and doodled my way through it.

But a shear deforms a small piece like this and it was bent and wobbly by about 8 thou.

I'll be aware of that in the future.

I brought it to a guy who has a surface grinder. Told him I don't care about the finish. Just flatten it.

It's within half a thou now.

I drilled the 4 holes 1/16" oversize so I can dial in a part in the 3 jaw then tighten the plate down.

By the way,

I'm starting to accept that I'm not a real machinist. I just make things so I can make things.