- Joined

- Nov 9, 2017

- Messages

- 222

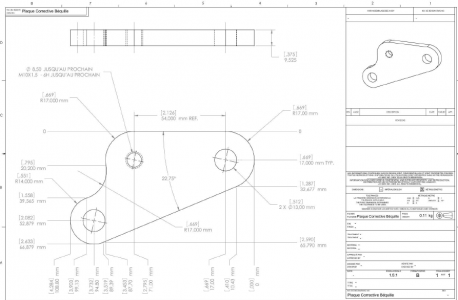

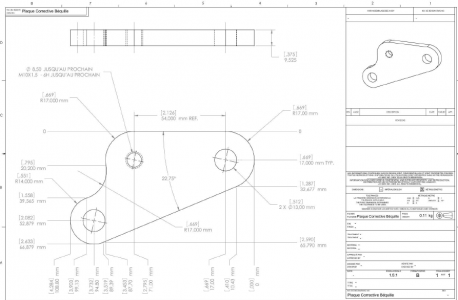

Hello All - I'm about to set up to start trying to produce the part shown below. I have a plate of aluminum about 12mm thick and 10-15mm larger in x and y dimensions than is necessary. My milling machine is manual, as is my lathe.

First question - to accurately drill/tap these holes in the correct positions I think I can just carefully move the right distances in X and Y. Is there a better way? I'm new to this and my tooling isn't built up substantially yet, don't have a swivel base for my vise etc.

Second question - is there any way with a manual machine I can produce the radiuses on the corners? I presume I'll make the entire part on the mill.

Nothing has to be super accurate in dimensions (+/- a mm for most aspects) except for the hole locations, because bolts will go through them into already made blind holes on the part this bolts to.

Thanks for any advice.

First question - to accurately drill/tap these holes in the correct positions I think I can just carefully move the right distances in X and Y. Is there a better way? I'm new to this and my tooling isn't built up substantially yet, don't have a swivel base for my vise etc.

Second question - is there any way with a manual machine I can produce the radiuses on the corners? I presume I'll make the entire part on the mill.

Nothing has to be super accurate in dimensions (+/- a mm for most aspects) except for the hole locations, because bolts will go through them into already made blind holes on the part this bolts to.

Thanks for any advice.