- Joined

- May 13, 2019

- Messages

- 1,016

Very exciting times. I finished my CNC conversion of my PM25 mill and made my first part. Since the CNC conversion kit I bought didn't have a cover for the column where the handwheel was located, I decided to make one. It's a simple project, but I learned a lot. I used FreeCAD for CAD/CAM and LinuxCNC on the mill PC.

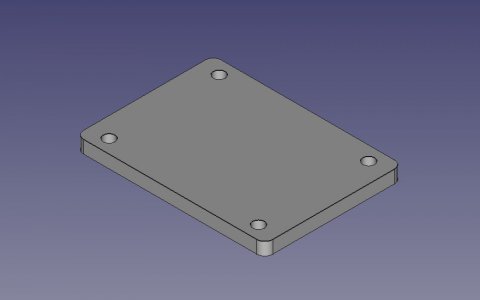

Heres' the 3D view of the part.

The biggest challenge was trying to determine how to hold this part since it's machined on all 4 sides. I came up with this for a solution.

1. Use a vise to hold the part and only do the drilling operation.

2. Clamp the part to the table with a 1-2-3 block underneath. Only clamp the 2 long sides in the middle. Set the Z distance so it clears everything. Use the quill to manually drop down to the part. As the tool nears the clamps, raise the quill. I single stepped the G-code for this.

3. After this is done, add clamps on the 2 short sides. Then, remove the clamps on the 2 long sides. This ensures the part doesn't move. Manually position the end mill and complete the uncut sections on the long sides.

Does anyone have suggestions on how to do this differently?

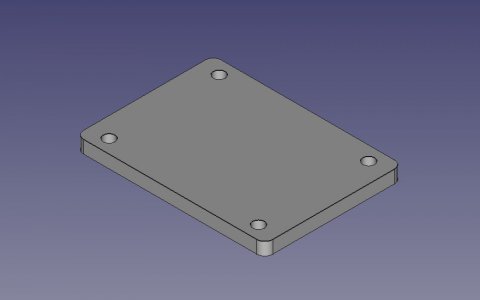

Take a look.

It turned out better than expected. As for dimension accuracy, I got about 0.002" undersize on the short dimension and about 0.003" oversize on the long dimension.

Heres' the 3D view of the part.

The biggest challenge was trying to determine how to hold this part since it's machined on all 4 sides. I came up with this for a solution.

1. Use a vise to hold the part and only do the drilling operation.

2. Clamp the part to the table with a 1-2-3 block underneath. Only clamp the 2 long sides in the middle. Set the Z distance so it clears everything. Use the quill to manually drop down to the part. As the tool nears the clamps, raise the quill. I single stepped the G-code for this.

3. After this is done, add clamps on the 2 short sides. Then, remove the clamps on the 2 long sides. This ensures the part doesn't move. Manually position the end mill and complete the uncut sections on the long sides.

Does anyone have suggestions on how to do this differently?

Take a look.

It turned out better than expected. As for dimension accuracy, I got about 0.002" undersize on the short dimension and about 0.003" oversize on the long dimension.