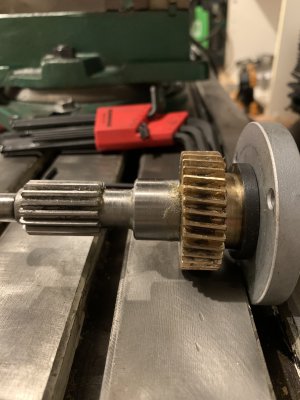

On the craftex cx601 same style as the grizzly g0704 or pm25 or pm30 when i try to lower the quill with the fine feed engaged it kinda works sometimes and then other times does not. The worm and wheel look ok to me. If I hold the brass gear in my hand and turn the handle it will slip a bit but there is definitely resistance. Any ideas?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

Fine feed slipping

- Thread starter Thriller

- Start date