- Joined

- Feb 28, 2019

- Messages

- 132

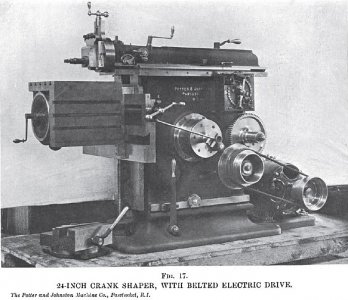

Took me like 5 years to do maybe 5 hours of work, but its fixed. Replaced the traversing shaft gearset a few yrs ago. put on a 5 hp motor last summer. 2 new belts this week. New lantern tool holder from casting, took about a year of hit and miss working on it. So, i oiled it up, threw some scrap in the vise, and plugged it in. Surprise!! smooth, quiet, and damn fun to use. took some fiddling, it was running backwards, wire swap. Stepping in cut stroke, simple adjustment. Set the stroke, and adjusted the height. did further carnage to a junk cylinder head Grabbed the first shaper ish tool bit i could find, and ran a pass. I used a 3/8 bit in my old lathe tool holder, as i dont have a 3/4 tool holder yet, and the final pass would work for most anything, i could get a real shiny finish with a larger bit, actually sharpened, but hey, i have a shaper. 2 days ago i had a project. This is a later model, mine is a converted line shaft with a 4 speed and an over center clutch.