Is the bevel angle on the face of a flycutter critical? One of my first projects after setting up my new bench top mill is an attempt at making my own flycutter. I've turned down the shank and head, but now I'm wondering how important is the angle of the face. I'm guessing 15 to 20 or 25 degrees. Am I missing some important factor in the desired angle? I'll be slotting the head to use 3/8th tool bits, if that matters.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Face angle for a homemade flycutter?

- Thread starter Nctox

- Start date

- Joined

- Nov 9, 2011

- Messages

- 263

On my commercially-made one, the face angle referenced to the work surface is 25 degrees. Personally, I wish it were more like 30 or slightly more, as a flatter angle can give you clearance problems depending on how your tool is ground. The flatter the angle, the farther you can extend your cutting radius, the higher the angle, the better the clearance. James Harvey, in his "Machine Shop Trade Secrets" book, even recommends 45 degrees. So the design is a tradeoff between clearance and radius, and the choice is up to you.

Just about nothing on a flycutter is critical. Precise angles are a matter of optimization for material, speed, etc.

Based on what I've seen and used, the angle between the cutter tip and the plane of the work being cut should be between 1* and 11*. 7* and 11* are common insert clearance angles, so the "seat" on your cutter need not include the angle.

For softer materials (aluminum, plastics, etc) look for a more acute angle, for harder materials look for a less acute angle. Do you plan on using inserts or HSS?

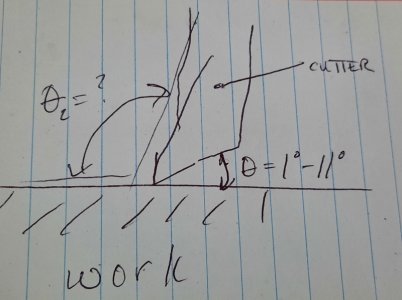

Edit: I think @Video_man and I are speaking of different angle locations. I'm referring to the angle between the bottom ("thickness") of the cutter and the work. Not to put words in anyone's mouth, but I suspect @Video_man is referring to the angle between the top (closest to vertical) edge of the cutter and the work. Here, a picture is definitely worth 1000 words...

GsT

Based on what I've seen and used, the angle between the cutter tip and the plane of the work being cut should be between 1* and 11*. 7* and 11* are common insert clearance angles, so the "seat" on your cutter need not include the angle.

For softer materials (aluminum, plastics, etc) look for a more acute angle, for harder materials look for a less acute angle. Do you plan on using inserts or HSS?

Edit: I think @Video_man and I are speaking of different angle locations. I'm referring to the angle between the bottom ("thickness") of the cutter and the work. Not to put words in anyone's mouth, but I suspect @Video_man is referring to the angle between the top (closest to vertical) edge of the cutter and the work. Here, a picture is definitely worth 1000 words...

GsT

Alright, pay attention, because clearly I spent hours on this precision drawing...

The angle I labeled with theta (1-11*) is the clearance. The angle labeled as theta(2) is what I think @Video_man was referencing.

Just to clear things up (I hope...).

GsT

The angle I labeled with theta (1-11*) is the clearance. The angle labeled as theta(2) is what I think @Video_man was referencing.

Just to clear things up (I hope...).

GsT

Attachments

- Joined

- Nov 9, 2011

- Messages

- 263

"Not to put words in anyone's mouth, but I suspect @Video_man is referring to the angle between the top (closest to vertical) edge of the cutter and the work. Here, a picture is definitely worth 1000 words..."

OK, here you go....OP asked about the angle of the face of the flycutter, nothing about the toolbit. He is making the flycutter body itself, the angle of the cutting tool is not part of the question.

OK, here you go....OP asked about the angle of the face of the flycutter, nothing about the toolbit. He is making the flycutter body itself, the angle of the cutting tool is not part of the question.

Attachments

Last edited: