- Joined

- Jan 24, 2015

- Messages

- 239

Dear All,

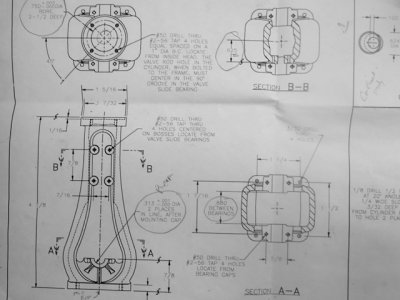

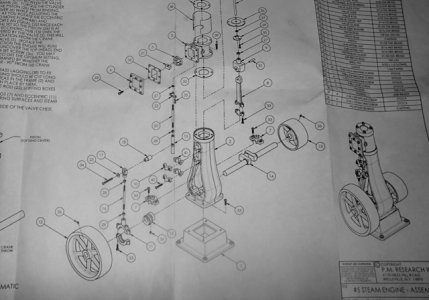

I am using the expanding mandrel idea in a current project. However, said idea is, when applied, less than solid. I am trying to hold a piece with a 3/4" bore. The piece is a small CI steam engine frame. My tool is a Sherline lathe (3.5 x 17).

So:

1) What are good vs bad metals to use for mandrels, given the size of the problem?

2) What is the most expansion one should target (as a proportion of diameter)?

3) What is the best way of getting expansion?

-How do you actually design you mandrel to expand? If using NPT taps and fittings, how do you judge depth of hole, depth of tap, distances, etc?

Thanks,

Tom

I am using the expanding mandrel idea in a current project. However, said idea is, when applied, less than solid. I am trying to hold a piece with a 3/4" bore. The piece is a small CI steam engine frame. My tool is a Sherline lathe (3.5 x 17).

So:

1) What are good vs bad metals to use for mandrels, given the size of the problem?

2) What is the most expansion one should target (as a proportion of diameter)?

3) What is the best way of getting expansion?

-How do you actually design you mandrel to expand? If using NPT taps and fittings, how do you judge depth of hole, depth of tap, distances, etc?

Thanks,

Tom