- Joined

- Jun 12, 2014

- Messages

- 5,055

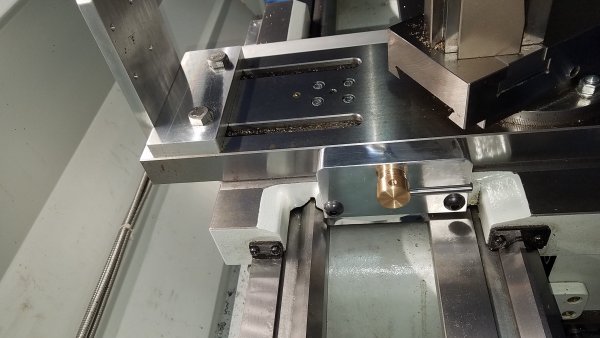

Often when doing tight tolerance work one needs to lock the cross slide to get consistent diameters along the length of the cut. My ERL-1340 was fairly tight when new, but over time I did noticed slight shifts in the cross slide position from my original setting. I am using glass scales, and I do not have access to the gib cross slide lock under the scale,. Using spacers between the carriage and DRO scale was not a good option because of the carriage design. In the past I fabricated a cross slide lock on the headstock side of the carriage, and opted fopr this approach for the RERL-1340. This one is made out of 25 mm wide aluminum bar stock with a lower cutout step so the face to carriage distance is about 0.01". The lock is 1" bronze rod with a 7/8-14 (UNF) thread which I cut to the shoulder, there are four 1/4-28 threaded holes at 90 degree intervals for the locking bar. All that is needed is about a 10 degree movement for full carriage lock. The lock mounts to the follow-rest mounting holes, and is easily removed if needed.

Cutting the 7/8-14 thread with a lay down threading insert at 350 RPM.

Installed.

Cutting the 7/8-14 thread with a lay down threading insert at 350 RPM.

Installed.