- Joined

- Nov 5, 2019

- Messages

- 233

Hello,

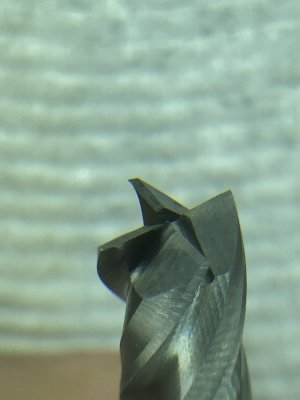

I picked up a whole box of end mills at an estate sale today cheap. Among then were a half dozen of these carbide 3/8 end mills still covered in wax. They were obviously resharpened but with a lot of relief behind the cutting edge. For what purpose would you need that much relief? Thanks for any input

I picked up a whole box of end mills at an estate sale today cheap. Among then were a half dozen of these carbide 3/8 end mills still covered in wax. They were obviously resharpened but with a lot of relief behind the cutting edge. For what purpose would you need that much relief? Thanks for any input