- Joined

- Dec 18, 2019

- Messages

- 7,428

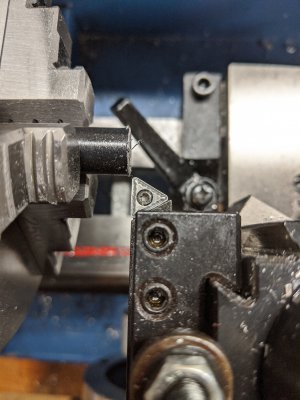

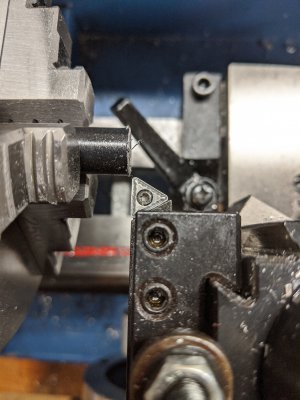

Have an LMS mini lathe. I ordered carbide bits with it, since I didn't really know what I was doing. So there are three bits in this kit. These are triangular indexable bits.

Sorry about the focus, I thought it was on the bits. How are they used? Starting from the tool on the right, we can mount this on a QCTP. For non facing, is the bit relative to the workpiece mounted like the picture below?

What should the angle be relative to the length of the piece? 90? I've read conflicting things, or I'm confused. So I'm asking for help. There are a lot of pictures (on this site) on HSS tool angles, but I haven't found anything on carbide tool positioning. As you can see from the 2nd photo, the facing that I did was ragged at best.

Sorry about the focus, I thought it was on the bits. How are they used? Starting from the tool on the right, we can mount this on a QCTP. For non facing, is the bit relative to the workpiece mounted like the picture below?

What should the angle be relative to the length of the piece? 90? I've read conflicting things, or I'm confused. So I'm asking for help. There are a lot of pictures (on this site) on HSS tool angles, but I haven't found anything on carbide tool positioning. As you can see from the 2nd photo, the facing that I did was ragged at best.