- Joined

- Mar 16, 2017

- Messages

- 148

I have been working on the Clough42 ELS on my PM-1340GT lathe and decided that if I am going to be using solid state electronics for the lead screw, than I might as well build solid state controls for the spindle. After all the VFD is a solid state device itself. Here is what I have so far:

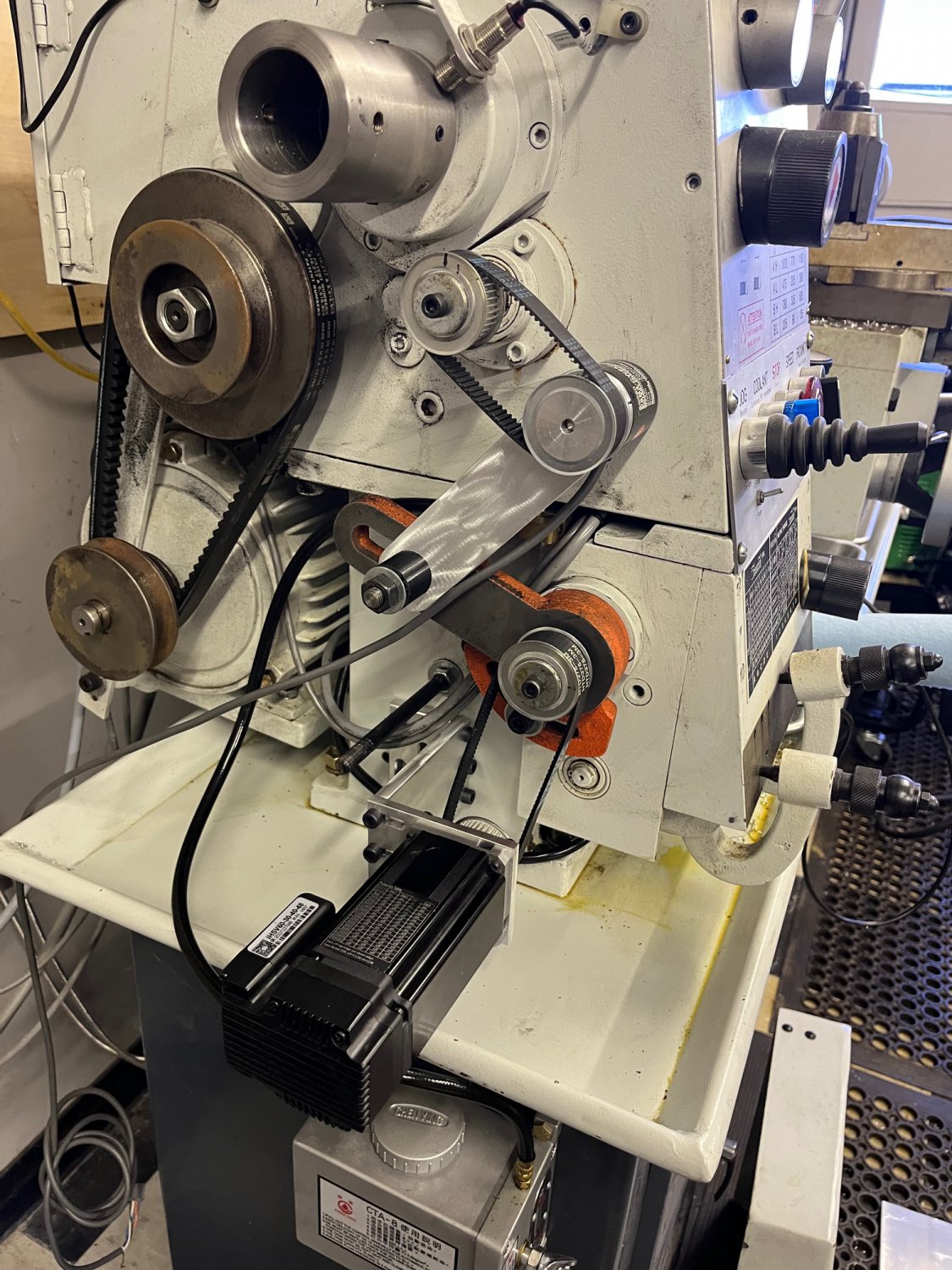

I have completed the installation of the servo and rotary encoder. I used the same mounting method as @xr650rRider used on his. My servo actually clears the gear cover with no modification.

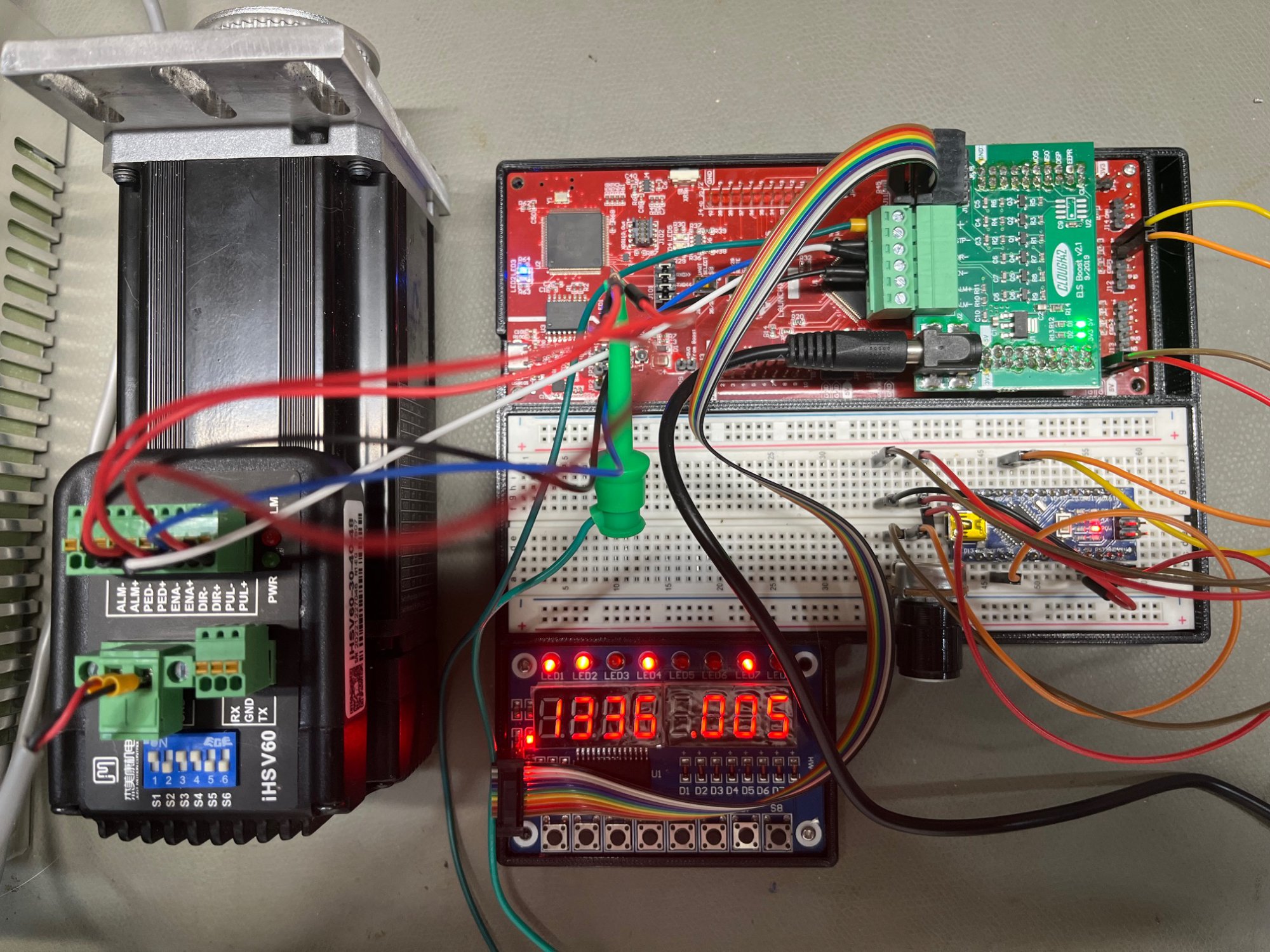

I have the ELS electronics in a test bed and everything works properly. You can see my test bed here:

For the solid state lathe controls I used a slightly modified version of the controls that were designed by @B2. More information can be found at https://www.hobby-machinist.com/thr...nents-pm1440gt-vfd-3-phase.95058/#post-883089.

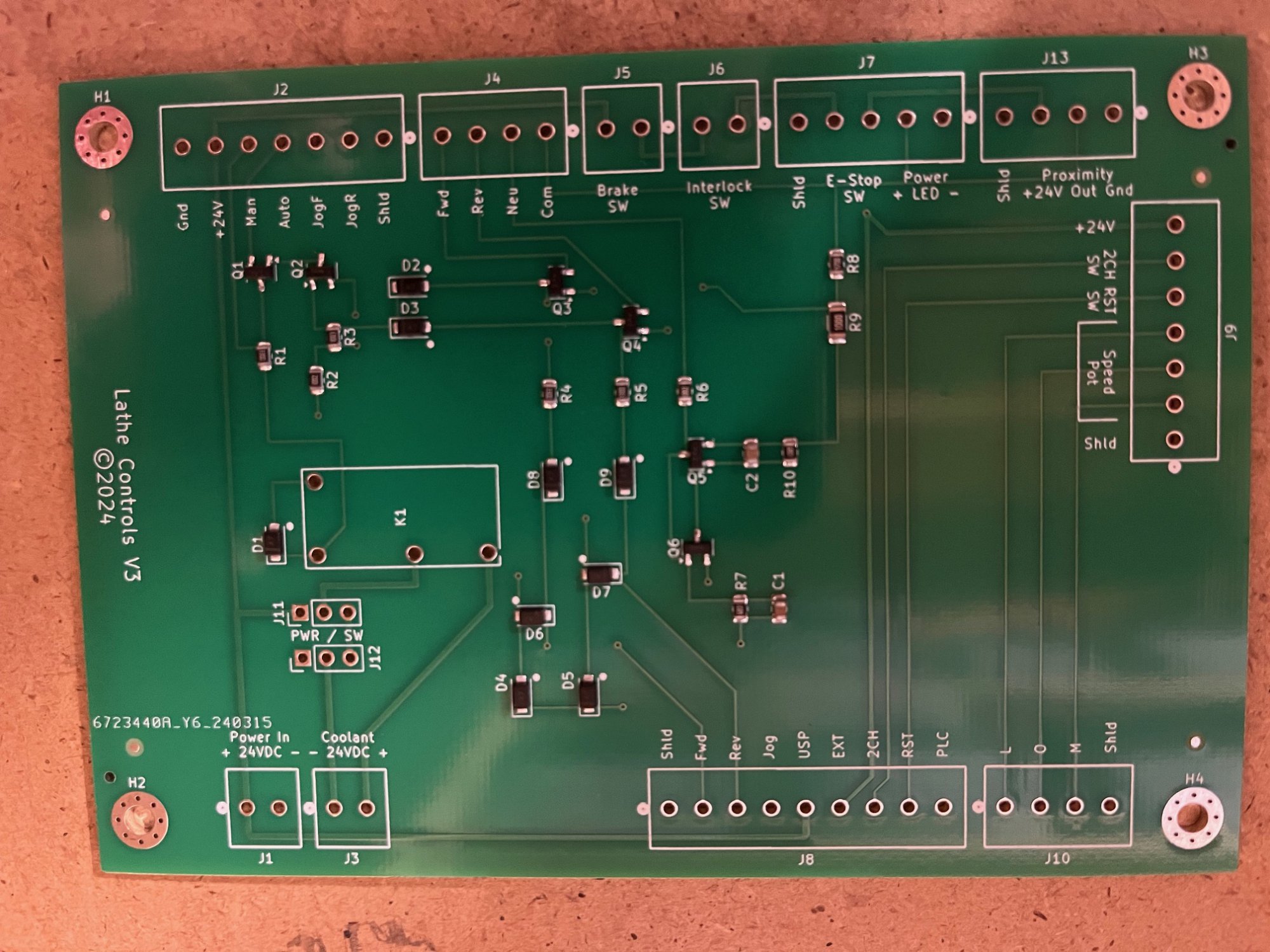

I designed the circuit using Kicad and had the printed circuit board built and the surface mounted devices installed by JLCPCB. The PCB cost about $4.00 from JLCPCB. I installed connectors and a relay on the board bringing the cost up to $30.00.

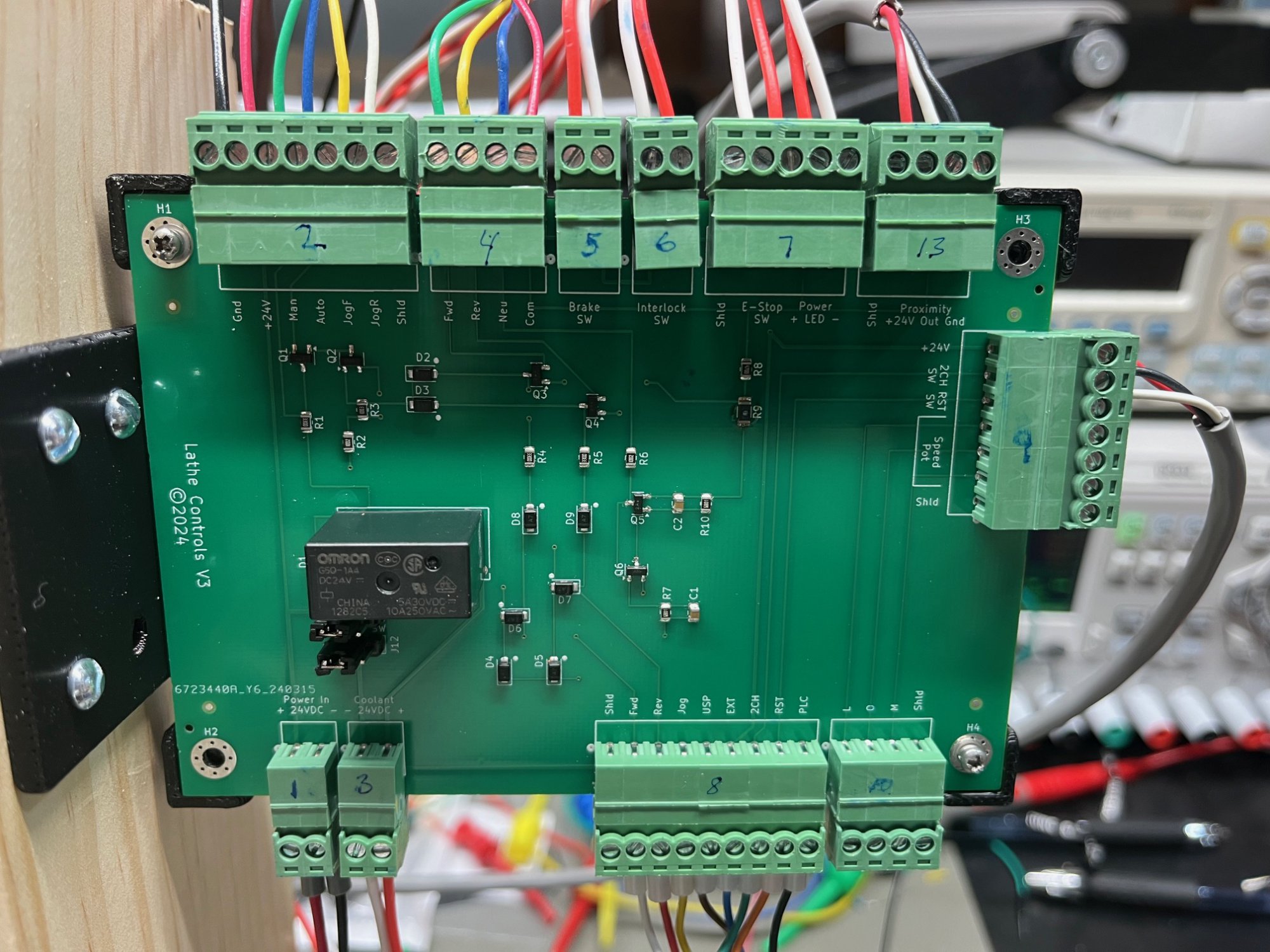

Here are pictures of the raw board as received from JLCPCB and after I installed the connectors.

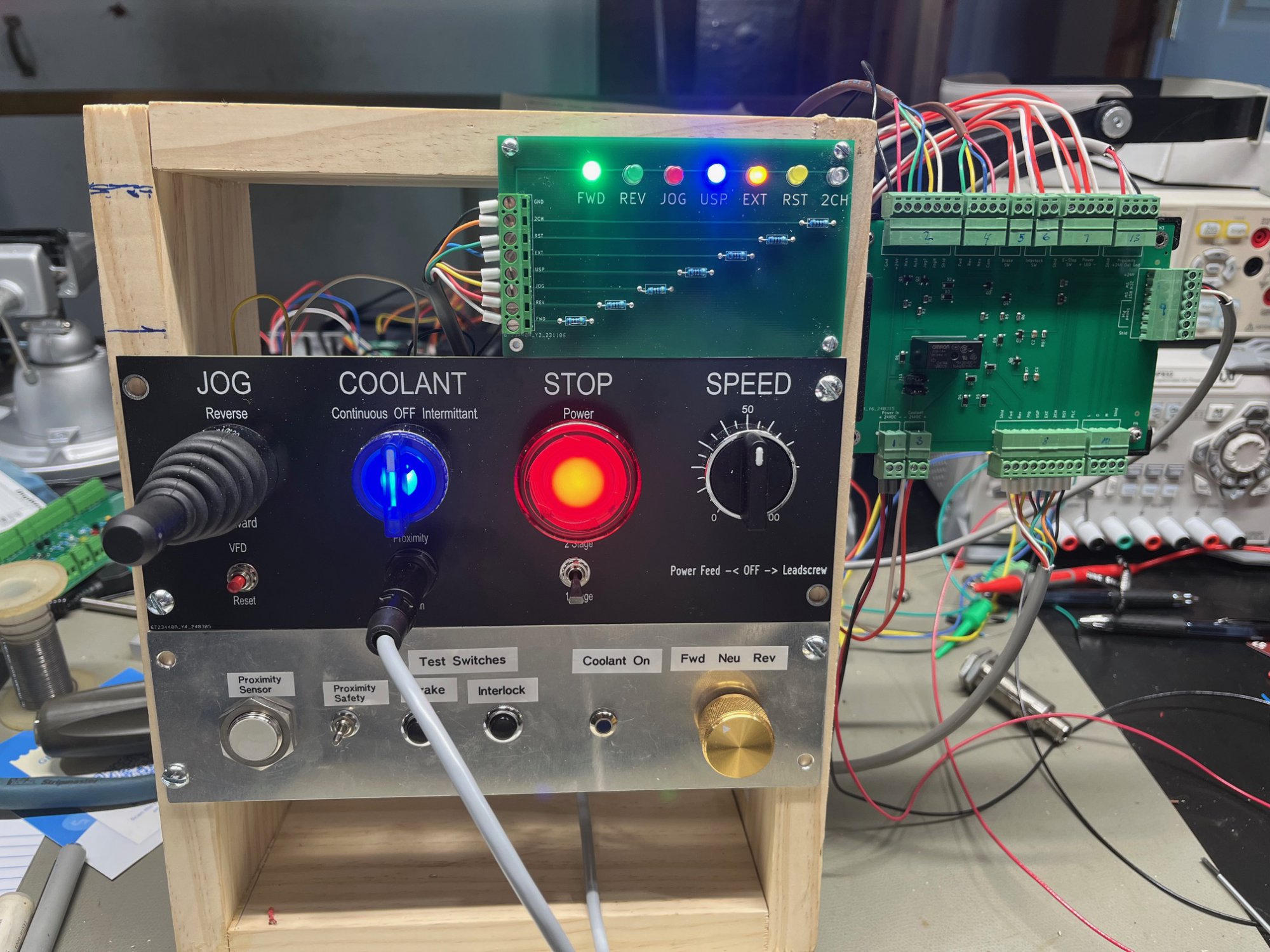

To test the lathe controls, I built a test bed that includes a front panel with all the switches as well as a panel that includes switches that are not on the front panel to simulate the brake switch, cover interlock switch and the proximity sensor, and the lathe forward/neutral/reverse switch. This way I could test all the functions of the board. To simulate the connection to the VFD, I built an LED board with an LED for each VFD input to verify that proper signals are output from the board for any control input. You can see that here.

Everything tested out perfectly so the next step is to build a new cabinet to hold my VFD as well as the ELS and control so that everything can be in one enclosure.

More to come in the future.

I have completed the installation of the servo and rotary encoder. I used the same mounting method as @xr650rRider used on his. My servo actually clears the gear cover with no modification.

I have the ELS electronics in a test bed and everything works properly. You can see my test bed here:

For the solid state lathe controls I used a slightly modified version of the controls that were designed by @B2. More information can be found at https://www.hobby-machinist.com/thr...nents-pm1440gt-vfd-3-phase.95058/#post-883089.

I designed the circuit using Kicad and had the printed circuit board built and the surface mounted devices installed by JLCPCB. The PCB cost about $4.00 from JLCPCB. I installed connectors and a relay on the board bringing the cost up to $30.00.

Here are pictures of the raw board as received from JLCPCB and after I installed the connectors.

To test the lathe controls, I built a test bed that includes a front panel with all the switches as well as a panel that includes switches that are not on the front panel to simulate the brake switch, cover interlock switch and the proximity sensor, and the lathe forward/neutral/reverse switch. This way I could test all the functions of the board. To simulate the connection to the VFD, I built an LED board with an LED for each VFD input to verify that proper signals are output from the board for any control input. You can see that here.

Everything tested out perfectly so the next step is to build a new cabinet to hold my VFD as well as the ELS and control so that everything can be in one enclosure.

More to come in the future.