Hi Ken, Guys,

The laser edge find that you see is my interpretation of one that I saw on the net a couple of years ago.

However if you want to build one it is very easy to make. A caveat first ! Find a suitable laser, not all lasers are suitable !

Let me explain, The first laser pointer that I tried didn't have a circular beam, the spot was actually a quite lobsided oval and produced a thick line.

Then I picked up this very cheap laser pointer in the local Aldi store.

View attachment 273761

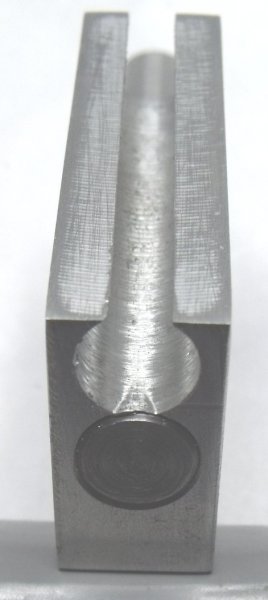

As you can see I broke it in half. The top bit is a ball point pen and a pullout pointer. I didn't need that bit. The bit that is needed is in the bottom half. Batteries and all. The button is one of those press and hold to turn the laser on. Testing this one I found that it produced a sharp round spot, ideal for this application. At a distance of 6" to 8" inches I get a bright round spot about 1.5 mm in diameter.

In the first picture of the previous post you can just see the button peeping out the side.

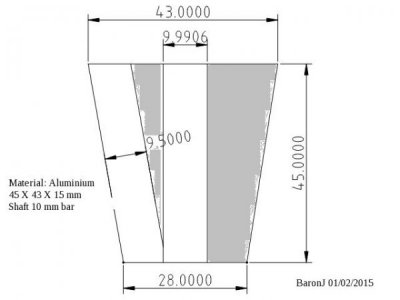

Once you have a suitable laser all you have to do is decide on the angle that you need to get the spot in the right place on the table. If I remember correctly, I used about 15 degrees. Then you need a suitable piece of aluminum plate, about 60 mm square or so and thick enough to drill for a spindle. I used a length of 1/2" inch drill rod. Then using a protractor to set the angle, clamped it in the mill vise and drilled a second hole so the two met at the bottom. The second hole was drilled with the same size drill. It turned out that 1/2" was the right size for the laser body.

At this point I had a square piece of 20 mm thick aluminum plate with two holes though it intersecting at one end. At this point I heated the plate and pressed the spindle into the first drilled hole. Using this spindle as a reference, I milled the two sides at an angle to match the angle of the laser pen body. I machined the non hole side first, so all I had to do was rotate the work 180 degrees to do the other side and machine a slot down that edge to clear the switch button.

View attachment 273762 View attachment 273763

One of the things that I aimed for when I made this, was symmetry. Though at the speed that you spin it, which isn't very fast, there is no noticeable out of balance. You will also notice that the spindle has deformed the metal in the hole that the laser fits into. This happens to be lucky chance, because it prevents the laser from slipping right through the hole.

I hope that I have given you enough information to go ahead and build one for yourself. If you have any questions just shout out. Being new to this web site I'm not sure exactly how that works, particularly when the notification Email I get informs me that I will not receive any further mail about this thread unless I visit it again. To be honest I'm not exactly thrilled at that !