- Joined

- Nov 10, 2013

- Messages

- 837

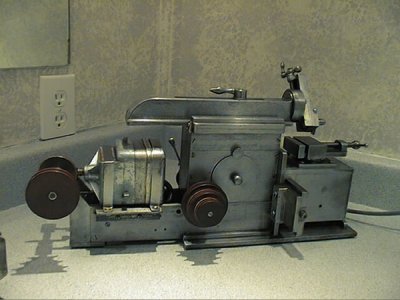

I posted a pic in another thread but couldn't remember if I'd ever mentioned the little shaper on this forum before. (I hate being "that guy" that reposts the same pics year after year.) I did a write up for an NEMES group many years ago, here's the text:

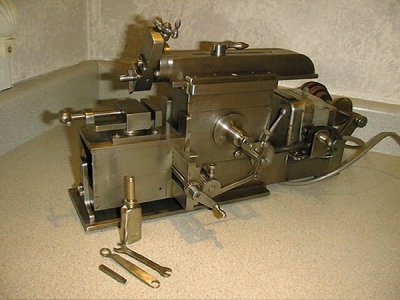

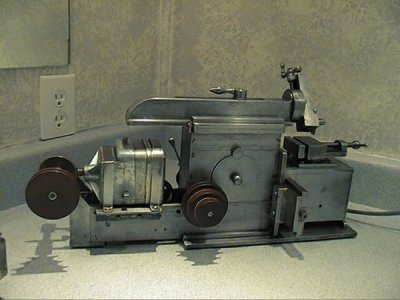

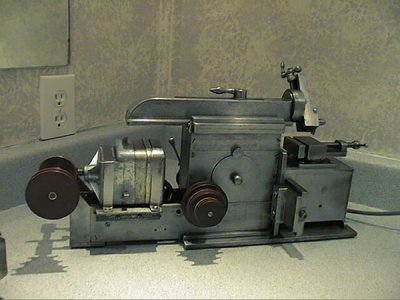

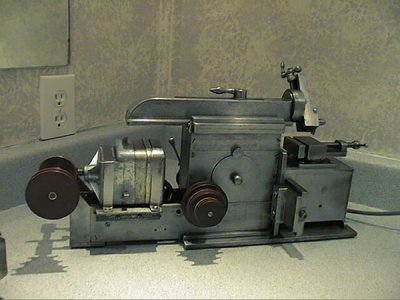

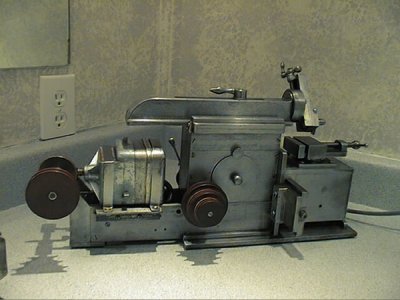

This miniature (working) shaper was made by his grandfather (Walter) around the depression era. The story is that he started a washing machine repair business using the shaper and a miniature lathe (which Mike has never seen) to make extra money to get through the depression. Mike’s grandfather made the shaper and lathe strictly by hand. He hack-sawed all CRS material by hand. He drilled the holes with a hand drill. He didn't even have a drill press until he made one. He had a grinder that Mike’s uncle (a retired tool maker) used to crank so he could sharpen his drills. The shaper is fully functional, has 6 speeds and is powered by a Victrola spring winding motor (motorized record playing turn tables weren't yet invented). Mike ran shapers in high school and in his apprenticeship in the tool trade. He says this little shaper has every feature of the big ones. The table actually raises and automatically feeds from side to side in both directions. The stroke is also adjustable.

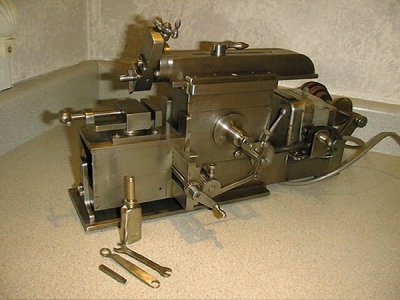

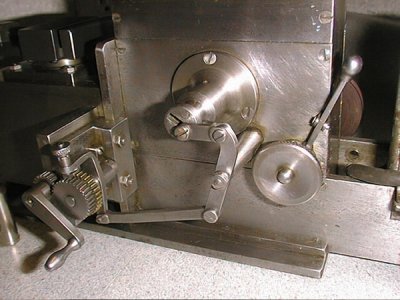

This little machine has a table cross-feed travel of 4", a table height adjustment of 2", and an adjustable ram stroke of up to 3". It uses a 90-degree gear reduction from its 0.7 amp motor to drive a three-step pulley on the RH side.

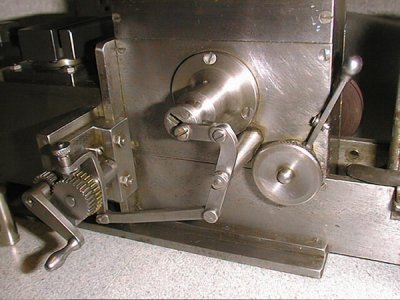

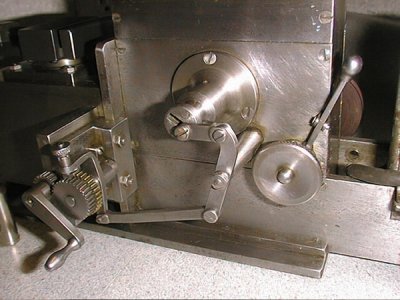

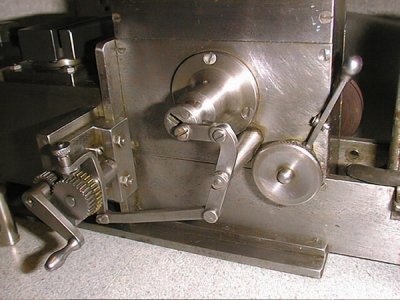

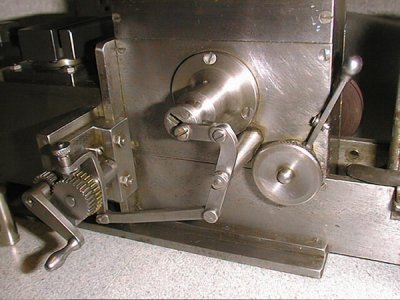

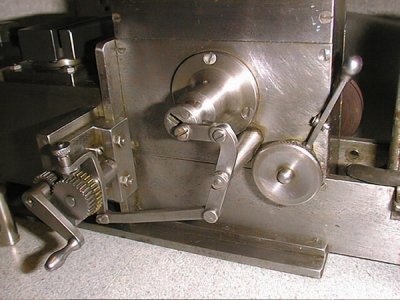

In the photo above, the lever near the rear is a two-speed gear change lever that increases the range to 6 speeds. The same photo shows a knob over the gear cluster on the left that, when rotated to engage gears, determines the direction of the automatic table feed.

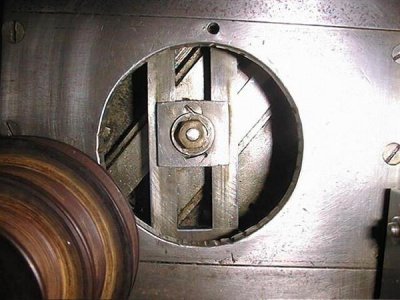

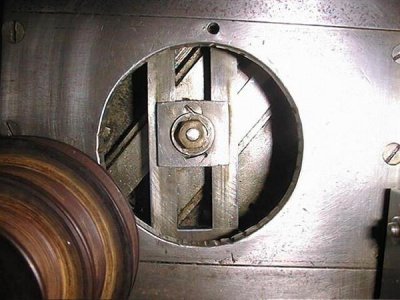

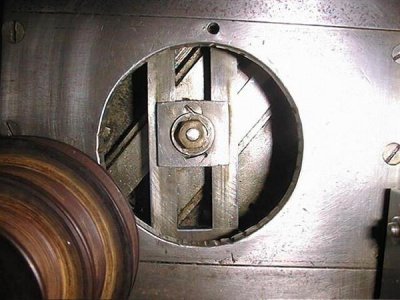

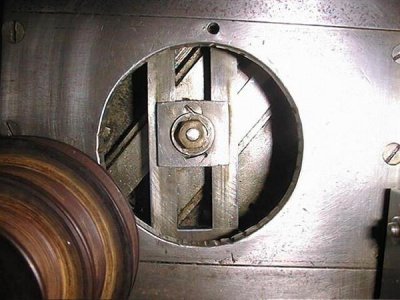

When the cover on the left hand side is removed, you can see the adjustment nut for the ram stroke, as shown in the photo below.

The toolbit down-feed mechanism is fully adjustable and rotates using radial t-slots similar to the setup on Bridgeport mills. The vise also rotates.

Walter came to the US from Poland as a young boy. He had no formal education. He is credited with inventing many common items, the most familiar of which is the flaring tool used to flair the ends of tubing. He was in the military at the time and received no patent in accordance with the laws of the time. He was born in Stryj Poland in 1896. He worked at Wright Patterson Air Force Base in Dayton Ohio twice, once before the war and again after. In his job application for Wright Patt in 1946 he listed patents and patents pending for a scrubbing and polishing machine and a strip of gang lights (used in bomber aircraft). He listed his hobbies as "developing mechanical machines, steam engines, gas engines, electric generating units, and steam turbines." (Mike has some of his engines too.) He retired from the Fabrication and Maintenance Division as a master machinist and certified inventor in 1960, making $3.49/hr.

He died in 1975. Mike inherited the shaper and will display it with his other collectible tools.

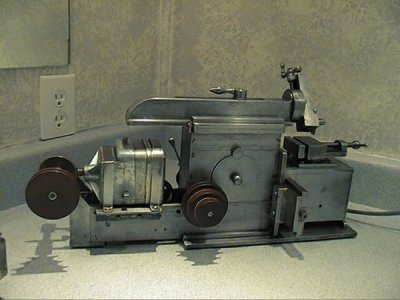

The photos of the shaper were taken on a bathroom countertop. Mike is willing to bet none of the members of NEMES has had a shaper in their bathroom yet!

That's the story, I got the details about the shaper from my uncle Ted (now deceased) about how the shaper was made. Here it sits today:

This miniature (working) shaper was made by his grandfather (Walter) around the depression era. The story is that he started a washing machine repair business using the shaper and a miniature lathe (which Mike has never seen) to make extra money to get through the depression. Mike’s grandfather made the shaper and lathe strictly by hand. He hack-sawed all CRS material by hand. He drilled the holes with a hand drill. He didn't even have a drill press until he made one. He had a grinder that Mike’s uncle (a retired tool maker) used to crank so he could sharpen his drills. The shaper is fully functional, has 6 speeds and is powered by a Victrola spring winding motor (motorized record playing turn tables weren't yet invented). Mike ran shapers in high school and in his apprenticeship in the tool trade. He says this little shaper has every feature of the big ones. The table actually raises and automatically feeds from side to side in both directions. The stroke is also adjustable.

This little machine has a table cross-feed travel of 4", a table height adjustment of 2", and an adjustable ram stroke of up to 3". It uses a 90-degree gear reduction from its 0.7 amp motor to drive a three-step pulley on the RH side.

In the photo above, the lever near the rear is a two-speed gear change lever that increases the range to 6 speeds. The same photo shows a knob over the gear cluster on the left that, when rotated to engage gears, determines the direction of the automatic table feed.

When the cover on the left hand side is removed, you can see the adjustment nut for the ram stroke, as shown in the photo below.

The toolbit down-feed mechanism is fully adjustable and rotates using radial t-slots similar to the setup on Bridgeport mills. The vise also rotates.

Walter came to the US from Poland as a young boy. He had no formal education. He is credited with inventing many common items, the most familiar of which is the flaring tool used to flair the ends of tubing. He was in the military at the time and received no patent in accordance with the laws of the time. He was born in Stryj Poland in 1896. He worked at Wright Patterson Air Force Base in Dayton Ohio twice, once before the war and again after. In his job application for Wright Patt in 1946 he listed patents and patents pending for a scrubbing and polishing machine and a strip of gang lights (used in bomber aircraft). He listed his hobbies as "developing mechanical machines, steam engines, gas engines, electric generating units, and steam turbines." (Mike has some of his engines too.) He retired from the Fabrication and Maintenance Division as a master machinist and certified inventor in 1960, making $3.49/hr.

He died in 1975. Mike inherited the shaper and will display it with his other collectible tools.

The photos of the shaper were taken on a bathroom countertop. Mike is willing to bet none of the members of NEMES has had a shaper in their bathroom yet!

That's the story, I got the details about the shaper from my uncle Ted (now deceased) about how the shaper was made. Here it sits today: