- Joined

- Sep 21, 2017

- Messages

- 119

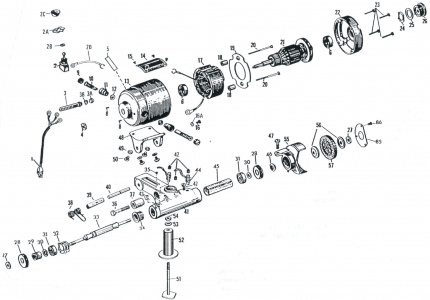

I purchased a used Dumore 8171 Series 44 toolpost grinder a while ago, and after purchasing a new drive belt I set it up to use for the first time. I don't have experience using these, but something doesn't seem right with the spindle bearings. There seems to be some endplay when I 'push' on the end where the grinder stone mounts, but it seems to be (lightly) spring-loaded. It seems to move about 40 thousandths (approx.), and has noticeable radial play as well. When I release my 'push', the spring returns the spindle to its normal position and takes up all the axial and radial play.

I'm not sure what to do, disassembling the spindle looks like it will require making some kind of spanner tool. Does anyone have experience with these spindles? Is this normal, or do I need to repair? Perhaps I just need to tighten something up?

I'm not sure what to do, disassembling the spindle looks like it will require making some kind of spanner tool. Does anyone have experience with these spindles? Is this normal, or do I need to repair? Perhaps I just need to tighten something up?