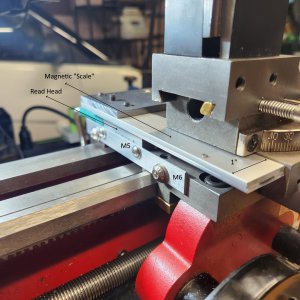

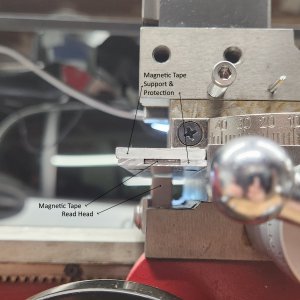

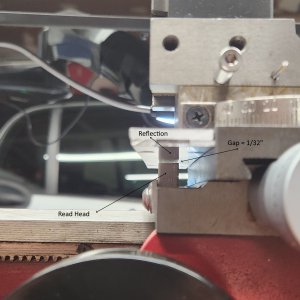

I'm about to replace the DRO glass scales on my lathe with magnetic scales. The X and Z axis glass scales are fixed positionally; the read heads travel with the cross-slide and carriage respectively, because glass scales integrate the read head with the scale, this arrangement made the most sense. Magnetic scales, at least the one's I've selected, separate the magnetic scale from the read head, they only require proximity tolerances to be respected.

Looking over the cross-slide installation today, it would be a lot easier, and more elegant, to fix the read head and let the magnetic tape travel. I've verified that the uninstalled scale works either way; it doesn't seem to care which part moves. But, before I make a dumb mistake, is there a compelling reason to have the read head travel, and fix the magnetic scale?

Thanks!

Looking over the cross-slide installation today, it would be a lot easier, and more elegant, to fix the read head and let the magnetic tape travel. I've verified that the uninstalled scale works either way; it doesn't seem to care which part moves. But, before I make a dumb mistake, is there a compelling reason to have the read head travel, and fix the magnetic scale?

Thanks!

but, since the read head and the scale are fully protected, and not physically connected to each other, they are more swarf-proof than integrated glass scales. We'll see, I may live to regret the decision

but, since the read head and the scale are fully protected, and not physically connected to each other, they are more swarf-proof than integrated glass scales. We'll see, I may live to regret the decision