Grab some popcorn, this is going to be a long post... I have to say that it was a mistake not doing more research before buying. I watched videos, read several threads on HM, and numerous members recommended magnetic scales, citing quality, reliability, etc., but I didn't pick up on the physical size difference of the scales and readers. Of course I took a look at them, but sticker shock got the best of me, and I ordered a glass scaled DRO from ebay.

As you can imagine, sticker shock was nothing compared to the size shock when I contemplated installing the glass scale on the cross slide of the lathe. I pondered my options for over a week, including trying to resell the whole thing on ebay and starting over (sticker shock be damned). Finally I decided to press forward. I figured I can always chuck it and start over down the road if I just can't stand the glass scale implementation. Based on that consideration, I set out to put as few holes as possible in my lathe in case I want to take another path.

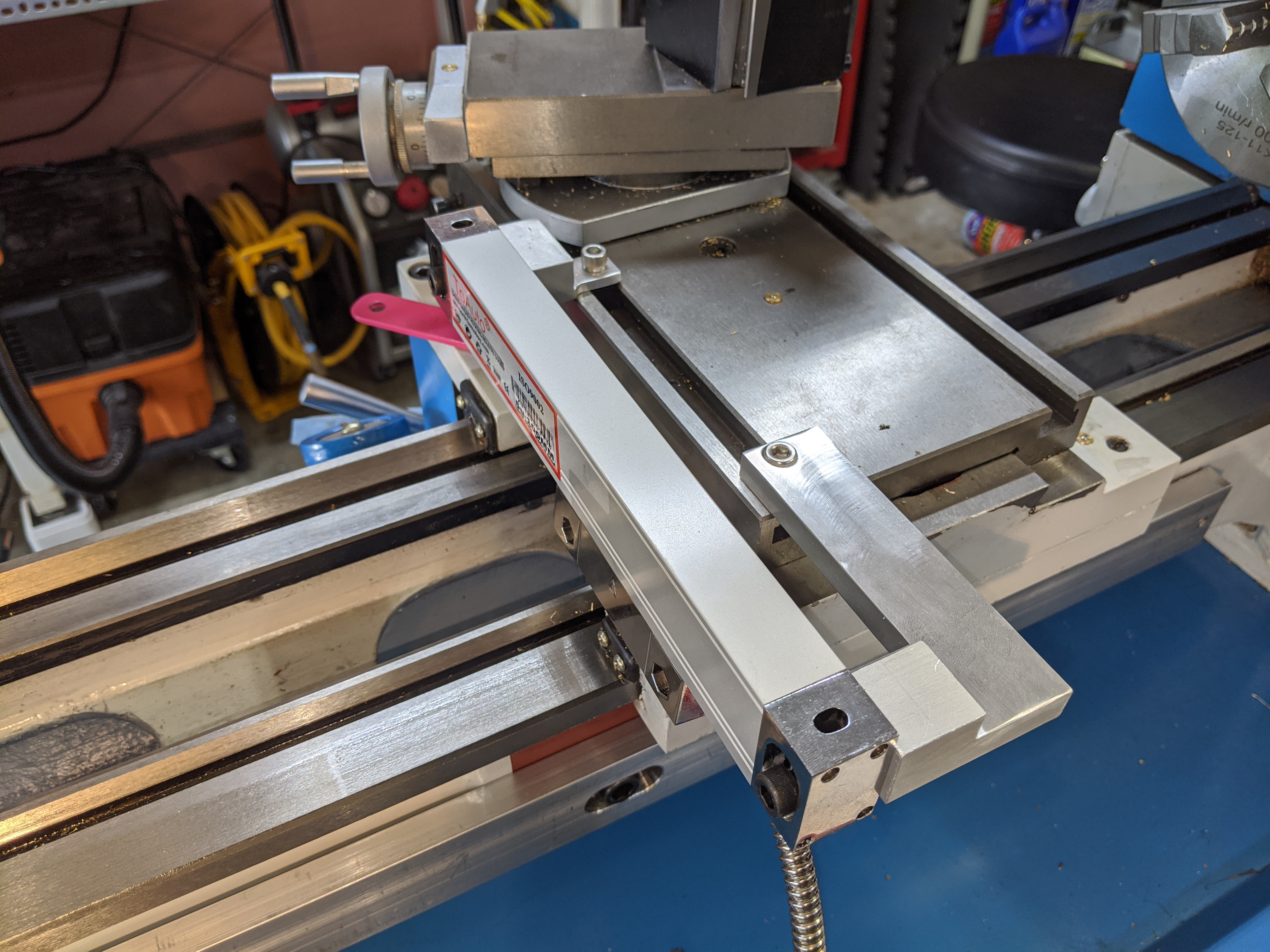

First I tackled the cross slide problem. As many of you know, the issue is maintaining access to the gib screws, cross slide lock, saddle lock, and oilers while minimizing the loss of tail stock travel. Installation is further complicated by the size of the read head on these scales as it will not fit between the ways on the PM1022, so the reader has to go on top of the saddle. It could set lower, right above the ways, but that means sacrifices another inch of tail stock travel and blocks horizontal access to the gib screws and lock. (I know... I could change them to hex head screws and access them from above.)

I was finally able to position the scale so that it does not hit the chip guard when the cross slide is cranked all of the way in. I really didn't want to ditch or relocate the chip guard. I opted to use the T-slots in the cross slide to mount this scale.

I possibly could move the scale closer to the cross slide, but I still have to fashion a cover for the scale/reader, and still have access to the saddle oilers.

And yes, the scale may interfere with the rotation of the compound, but the scale can be removed with three screws if needed.

After that, the Z-axis was a piece of cake. I opted to use the existing M10 holes in the lathe bed, and used an aluminum bar as a mount, tapped at each end for the scale, and on top for the guard.

I realized that I could tie both read heads to a single mount point. The lip on the bottom rigidly locates the piece with only one hole drilled into the saddle.

X-axis mount...

I always struggle with web post photos, trying to figure out what I'm looking at, so here's the complete reader mount assembly.

and.... done, the one hole wonder.

So far, I'm pleased with the install. Still need to fab the cover for the X-axis, and figure out the cryptic user manual.

As you can imagine, sticker shock was nothing compared to the size shock when I contemplated installing the glass scale on the cross slide of the lathe. I pondered my options for over a week, including trying to resell the whole thing on ebay and starting over (sticker shock be damned). Finally I decided to press forward. I figured I can always chuck it and start over down the road if I just can't stand the glass scale implementation. Based on that consideration, I set out to put as few holes as possible in my lathe in case I want to take another path.

First I tackled the cross slide problem. As many of you know, the issue is maintaining access to the gib screws, cross slide lock, saddle lock, and oilers while minimizing the loss of tail stock travel. Installation is further complicated by the size of the read head on these scales as it will not fit between the ways on the PM1022, so the reader has to go on top of the saddle. It could set lower, right above the ways, but that means sacrifices another inch of tail stock travel and blocks horizontal access to the gib screws and lock. (I know... I could change them to hex head screws and access them from above.)

I was finally able to position the scale so that it does not hit the chip guard when the cross slide is cranked all of the way in. I really didn't want to ditch or relocate the chip guard. I opted to use the T-slots in the cross slide to mount this scale.

I possibly could move the scale closer to the cross slide, but I still have to fashion a cover for the scale/reader, and still have access to the saddle oilers.

And yes, the scale may interfere with the rotation of the compound, but the scale can be removed with three screws if needed.

After that, the Z-axis was a piece of cake. I opted to use the existing M10 holes in the lathe bed, and used an aluminum bar as a mount, tapped at each end for the scale, and on top for the guard.

I realized that I could tie both read heads to a single mount point. The lip on the bottom rigidly locates the piece with only one hole drilled into the saddle.

X-axis mount...

I always struggle with web post photos, trying to figure out what I'm looking at, so here's the complete reader mount assembly.

and.... done, the one hole wonder.

So far, I'm pleased with the install. Still need to fab the cover for the X-axis, and figure out the cryptic user manual.