- Joined

- Aug 6, 2013

- Messages

- 336

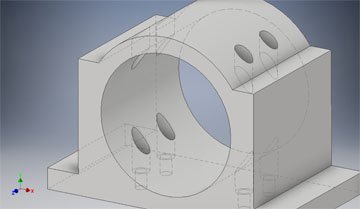

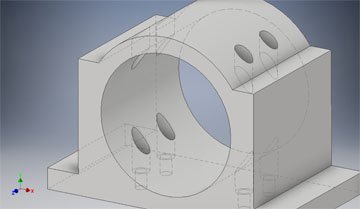

Ok, I'm sure the smart way to drill the 4 through holes and then drill or machine the countersink pockets would be to do so before it was machined. But this is a precast aluminum spindle mount for a cnc router and I want to do so to fit my existing Z fixture's threaded mounting holes. I can drill the through holes from the bottom. But is there a recommended way to machine the pockets other than just use a center cutting end mill and vertically plunge them carefully? I have a long enough end mill, but none small enough diameter that long to allow helical pocketing or ramping on my cnc mill. Hopefully the photo is large enough to see the lines in the drawing where the holes/pockets go.

Last edited: