- Joined

- Mar 5, 2023

- Messages

- 97

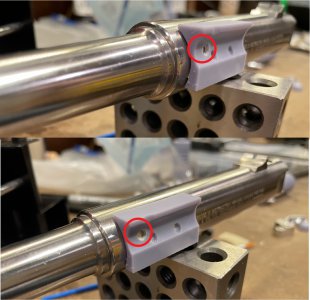

I need to drill and tap an M4 hole in the barrel of this stainless Ruger Mark II. The photos below show a plastic site mount that needs to sit just right on the side of the barrel. The hole that I will need to make is circled in red.

The part that concerns me is the angle that I'll need to come at the barrel. It's off center and I'm concerned that anything I came at it with will just glance off. I'll be using my LMS 3990 mini mill for this operation.

Any tips or advice would be greatly appreciated.

The part that concerns me is the angle that I'll need to come at the barrel. It's off center and I'm concerned that anything I came at it with will just glance off. I'll be using my LMS 3990 mini mill for this operation.

Any tips or advice would be greatly appreciated.