- Joined

- Oct 7, 2020

- Messages

- 2,347

I was playing around in Fusion 360 tonight trying to draw an outdoor metal rack for a bunch of used metal that I have just stacked on the ground behind the shop.

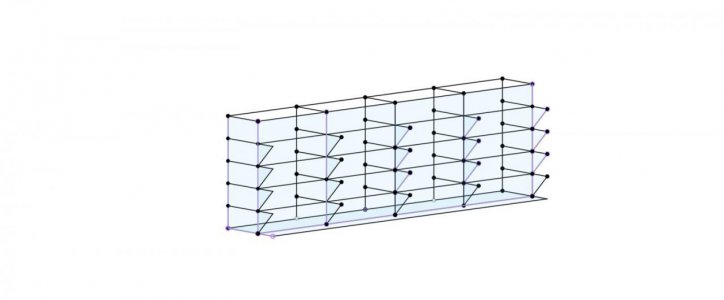

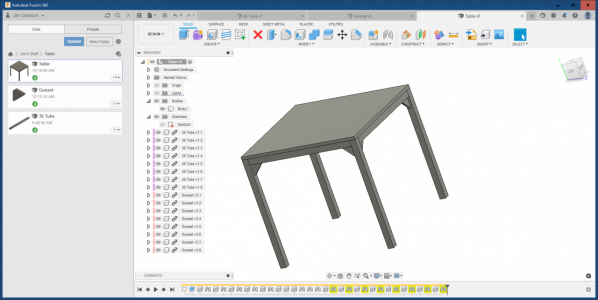

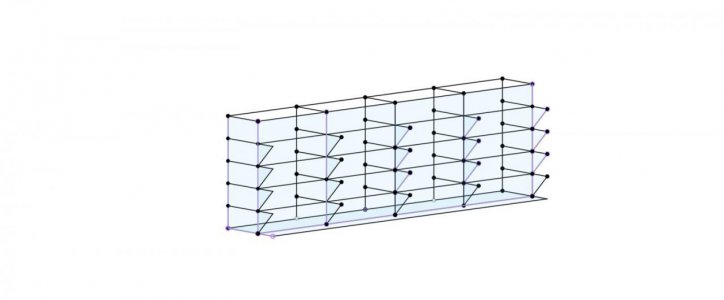

I have somewhat of the basic design down. But now I want to change some things and add others. To start with I made it 16' long 2-point rectangle with the origin in the mid-point of one of the long sides. I would like to change it to 12' but the problem is sense I centered the drawing mid-point the program decreases the size at least from the base from both sides. I also wanted to put a shelf of the front edge if you will at 12" wide. I have a total of eight sketches.

What I have drawn right now is 16' long 3' wide by 5' tall with 5 uprights and 5 cross pieces that are 2' wide. The cross pieces are actually 3' wide, but one foot extends 1' past the upright for a mesh shelf of some sort for small items.

So, I realize it's probably just about impossible to tell someone in a forum like this how to draw in Fusion 360. But how or what is the right way to draw something like this. I'm thinking it is considered a 2D drawing, but when I search 2D drawing all I can find is make a 2D drawing from a design.

I have included a screen shot to get an idea of what I was trying to do. I don't know how or even if I can share the drawing I am working on.

Tim

I have somewhat of the basic design down. But now I want to change some things and add others. To start with I made it 16' long 2-point rectangle with the origin in the mid-point of one of the long sides. I would like to change it to 12' but the problem is sense I centered the drawing mid-point the program decreases the size at least from the base from both sides. I also wanted to put a shelf of the front edge if you will at 12" wide. I have a total of eight sketches.

What I have drawn right now is 16' long 3' wide by 5' tall with 5 uprights and 5 cross pieces that are 2' wide. The cross pieces are actually 3' wide, but one foot extends 1' past the upright for a mesh shelf of some sort for small items.

So, I realize it's probably just about impossible to tell someone in a forum like this how to draw in Fusion 360. But how or what is the right way to draw something like this. I'm thinking it is considered a 2D drawing, but when I search 2D drawing all I can find is make a 2D drawing from a design.

I have included a screen shot to get an idea of what I was trying to do. I don't know how or even if I can share the drawing I am working on.

Tim