4

4GSR

Forum Guest

Register Today

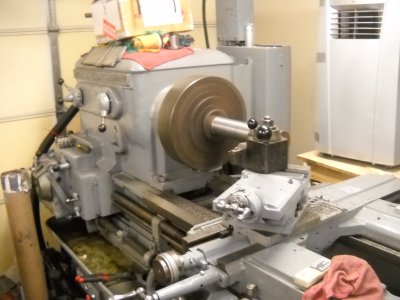

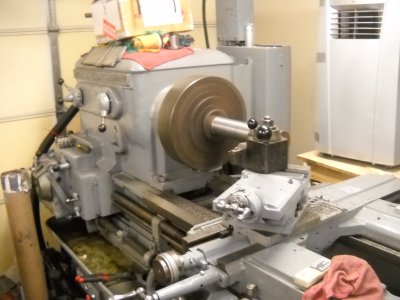

Just got my 20" Lodge & Shipley lathe up and running for the first time since I finished the rebuilding process that has taken me almost 6 years to do.

First thing I did is make sure the bed is not twisted. I know this method is not the way some people like to do it, but if you know your machine and what you are doing, this is the way to level it. I don't worry about leveling the bed length wise unless you have a center leg on the bed like I do on this lathe.

I took a rough cut over the bar stock to remove the rust and crud. Next change my tool to a positive rake zero honed edge tool and take a .015-.020" depth cut. You can undercut the middle of the bar if you like. I don't want to waste a good piece of bar stock taking the cut too deep. I can still take this piece of stock to 2.750" OD if I have a need to do so. The amount of taper I came up with was 0.001" in 12". It is larger at the chuck end and smaller at the tailstock end. Don't tell me it's flex in the bar stock causing the taper! I know better.

Enjoy! Ken

First thing I did is make sure the bed is not twisted. I know this method is not the way some people like to do it, but if you know your machine and what you are doing, this is the way to level it. I don't worry about leveling the bed length wise unless you have a center leg on the bed like I do on this lathe.

I took a rough cut over the bar stock to remove the rust and crud. Next change my tool to a positive rake zero honed edge tool and take a .015-.020" depth cut. You can undercut the middle of the bar if you like. I don't want to waste a good piece of bar stock taking the cut too deep. I can still take this piece of stock to 2.750" OD if I have a need to do so. The amount of taper I came up with was 0.001" in 12". It is larger at the chuck end and smaller at the tailstock end. Don't tell me it's flex in the bar stock causing the taper! I know better.

Enjoy! Ken