-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY tangential tool | Diamond Tool Holder and plans in video description

- Thread starter celsoari

- Start date

- Joined

- Nov 29, 2017

- Messages

- 183

Thanks Brino.I've have wanted to build one of these.

I really like your design.

Thanks for sharing it!

-brino

cheers

Celso Ari

- Joined

- Oct 14, 2014

- Messages

- 2,114

Just curious, unless its a HUGE amount of material, I never saw out sections like done at the beginning of the video. Time saved removing material is lost re-trueing up IMHO. Both ways certainly work. Maybe I like my method cause i got a 5hp spindle and carbide insert cutters for hogging. Corn cob cutters work great too. What is the general opinion here on hobby machinist?

- Joined

- Nov 29, 2017

- Messages

- 183

what is IMHO? sorry here we speak portuguese, i am not fluent in english, so i have difficulty understanding some word suppressions

Just curious, unless its a HUGE amount of material, I never saw out sections like done at the beginning of the video. Time saved removing material is lost re-trueing up IMHO. Both ways certainly work. Maybe I like my method cause i got a 5hp spindle and carbide insert cutters for hogging. Corn cob cutters work great too. What is the general opinion here on hobby machinist?

- Joined

- Jan 2, 2014

- Messages

- 9,226

What is the general opinion here on hobby machinist?

Interesting question..........

I guess it comes down to what is easier/cheaper for any given operation.....and that depends on what machine tools are in the shop and whether it's a production shop or a hobby shop. It comes down to a time required for the operation.

-brino

- Joined

- Jul 28, 2017

- Messages

- 2,561

Owning a small desktop mill, hogging out large amounts of metal is very time-consuming for me. So I look for ways to speed things up where I can. Depending on the item I'm making, I may use my bandsaw to rough out some portions. In others, I will use my slitting saw instead of turning the whole volume of removed metal into small bits of swarf. If feasible, I also have separated the item into several different pieces and then assembled them into a whole.

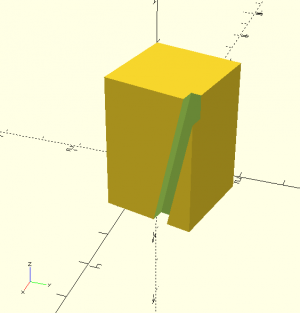

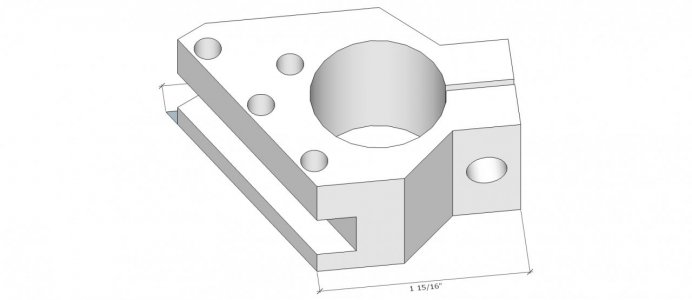

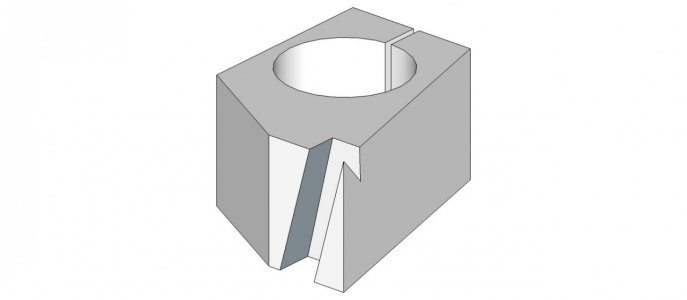

I found a design for a tangential tool holder that uses the latter approach, and, in addition, splits the two different angles among two separate parts, rather than needing a complicated setup to mill the compound angle needed for a one-piece approach. This should work OK for me because I'm using a Norman Patent style of QCTP and can split the angles between the main block (that mounts on the post) and a second piece that will bolt onto a sloped face of the block. The design can be found in the groups.io 7x12 mini lathe file section, titled "Mini Lathe Diamond Tool Holder.pdf". Folks who have dovetail-style QCTPs may not find this approach all that interesting.

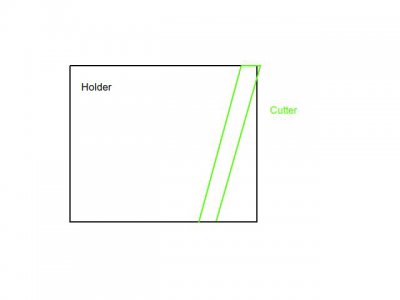

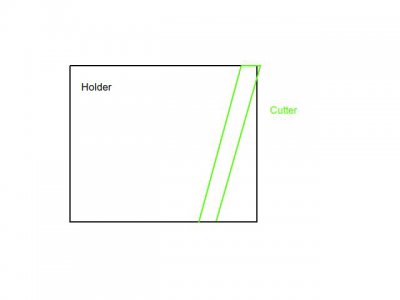

I'm wondering about a design that uses an even simpler scheme to achieve the required clearances. Mill an angled vertical slot on the face of the QCTP block, then rotate it by a small angle when you install it on the lathe. Just one easy-to-mill angle. Here's a sketch showing the working face of such a holder, with a cutter installed:

In this view, the upper-right corner of the cutter is presented to the work, so I'm showing the back of the holder relative to the operator, Not shown: the holder is rotated so the tip of the cutter is pointing slightly away from you.

NOTE: I edited this because I originally (and mistakenly) indicated that the holder needs to be rotated CCW, and thus can't foul the chuck, but that was incorrect. The holder must be rotated CW to get the proper relief angles. However, I still don't think the holder is likely to strike the chuck before the cutter would. This due to the fact that the chuck jaws extend from the front of the chuck, so there's some leeway there.

If oriented correctly, I'm thinking this holder could also be used to face a workpiece, too.

Not shown: fixing screws to hold the cutter in place. Oh, and the grind angle of the cutter isn't right -- it should be arranged so there's some positive rake when it's presented to the work (it IS just a sketch, right?).

I found a design for a tangential tool holder that uses the latter approach, and, in addition, splits the two different angles among two separate parts, rather than needing a complicated setup to mill the compound angle needed for a one-piece approach. This should work OK for me because I'm using a Norman Patent style of QCTP and can split the angles between the main block (that mounts on the post) and a second piece that will bolt onto a sloped face of the block. The design can be found in the groups.io 7x12 mini lathe file section, titled "Mini Lathe Diamond Tool Holder.pdf". Folks who have dovetail-style QCTPs may not find this approach all that interesting.

I'm wondering about a design that uses an even simpler scheme to achieve the required clearances. Mill an angled vertical slot on the face of the QCTP block, then rotate it by a small angle when you install it on the lathe. Just one easy-to-mill angle. Here's a sketch showing the working face of such a holder, with a cutter installed:

In this view, the upper-right corner of the cutter is presented to the work, so I'm showing the back of the holder relative to the operator, Not shown: the holder is rotated so the tip of the cutter is pointing slightly away from you.

NOTE: I edited this because I originally (and mistakenly) indicated that the holder needs to be rotated CCW, and thus can't foul the chuck, but that was incorrect. The holder must be rotated CW to get the proper relief angles. However, I still don't think the holder is likely to strike the chuck before the cutter would. This due to the fact that the chuck jaws extend from the front of the chuck, so there's some leeway there.

If oriented correctly, I'm thinking this holder could also be used to face a workpiece, too.

Not shown: fixing screws to hold the cutter in place. Oh, and the grind angle of the cutter isn't right -- it should be arranged so there's some positive rake when it's presented to the work (it IS just a sketch, right?).

Last edited:

- Joined

- Jul 28, 2017

- Messages

- 2,561