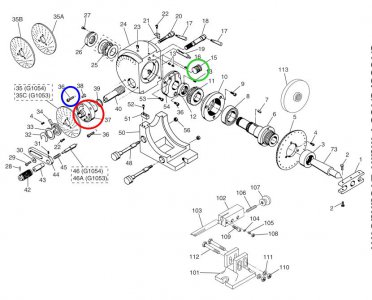

I bought a $200 ebay BS-0 head and have some questions. I broke it down and cleaned it, it was surprising clean actually. I've watched several youtube videos where this head is broken down and reassembled, but everyone kind of speeds based the section on getting the worm gear setup properly. If you look at my picture below (taken from the grizzly manual) Forgive me if im naming these parts incorrectly, but...

The PLUG in the GREEN circle appears to center the worm gear

The CAM in the RED circle rotates about 90 degrees to lock/release the worm gear

The SCREW in BLUE limits the rotation of the CAM.

I can adjust the plug screw in and out several rotations and the mechanism still functions smoothly, there doesn’t appear to be one sweet spot. My issue is this, no matter how I adjust the PLUG, my CAM seems to be either too lose or too tight. If I tighten the SCREW too much, the cam is difficult to lock and release. If I keep the SCREW lose, the operation is smooth, but when I rotate the handle, the cam will quickly slide down to the unlocked position. I kind of have to use two hands, one to hold the cam up and one to rotate the handle. I cannot seem to get any improvement regardless of how lose or tight the screw is, and no matter how much I adjust the PLUG in out out. It may also be worth noting that my CAM has only one position screw, and not two like in this picture (part #36)

Can anyone assist?

The PLUG in the GREEN circle appears to center the worm gear

The CAM in the RED circle rotates about 90 degrees to lock/release the worm gear

The SCREW in BLUE limits the rotation of the CAM.

I can adjust the plug screw in and out several rotations and the mechanism still functions smoothly, there doesn’t appear to be one sweet spot. My issue is this, no matter how I adjust the PLUG, my CAM seems to be either too lose or too tight. If I tighten the SCREW too much, the cam is difficult to lock and release. If I keep the SCREW lose, the operation is smooth, but when I rotate the handle, the cam will quickly slide down to the unlocked position. I kind of have to use two hands, one to hold the cam up and one to rotate the handle. I cannot seem to get any improvement regardless of how lose or tight the screw is, and no matter how much I adjust the PLUG in out out. It may also be worth noting that my CAM has only one position screw, and not two like in this picture (part #36)

Can anyone assist?