- Joined

- Jan 6, 2017

- Messages

- 1,248

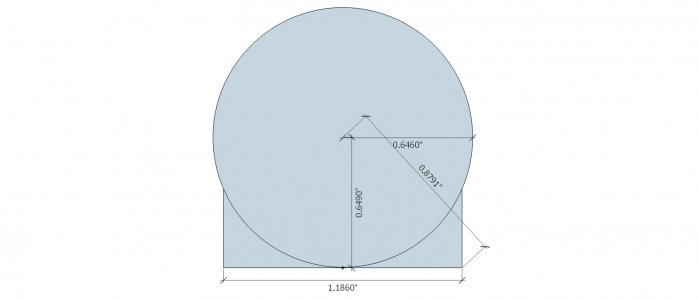

I have a design and already have the materials on-hand to fabricate this d1-4 spider chuck. I'm using a Shars 5" d1-4 back plate and a 4-3/4" x 6" piece of 8620 rod I picked up on ebay for 50$.

The screw placement and spacing should allow me to dial in most long and short action receivers and bolt bodies.

One thing I'm uncertain of though, is the minimum bore diameter I would need to fit Winchester and Howa type flat bottom receivers. It doesn't need to allow the recoil lug into the bore, that can be left outside. It only needs enough ID to fit the body of those flat bottom receivers.

Anyone happen to know how big the bore would need to be to fit a Winchester 70 and/or Howa 1500?

The screw placement and spacing should allow me to dial in most long and short action receivers and bolt bodies.

One thing I'm uncertain of though, is the minimum bore diameter I would need to fit Winchester and Howa type flat bottom receivers. It doesn't need to allow the recoil lug into the bore, that can be left outside. It only needs enough ID to fit the body of those flat bottom receivers.

Anyone happen to know how big the bore would need to be to fit a Winchester 70 and/or Howa 1500?