- Joined

- May 5, 2017

- Messages

- 5

I was told by an old and trusted member of the foundry industry to cast my fan blades in carbon fiber. He's built a Lancair and knows a bunch about carbon fiber and things aeronautical.

I had planned on designing a mold for a 2-part polyurethane foam but might as well go with carbon fiber if it's doable. I have zero experience in designing a mold so am asking for pointers.

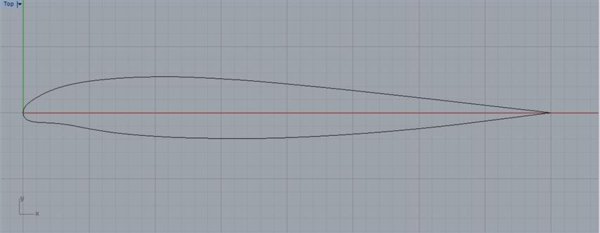

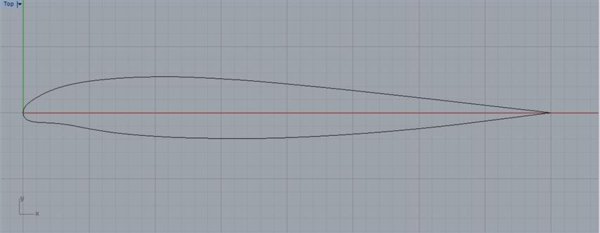

The fan blade is based on a Cessna (NACA 2412) airfoil. It's chord is 39.9mm and height is 37.5mm. I'd originally thought I'd design the mold with the blade laying horizontally in the cavity, but since I'm putting a Sportsman STOL leading edge on it, there's no way I can think of to do it without having a parting line near the leading edge which is unacceptable (a parting line near the leading edge would encourage a stall of the blade). So, I'll likely have to design the mold with the leading and trailing edges of the blade/airfoil vertical. I don't mind the draft, tapered wings are everywhere. Why not in my fan? That way the parting line could be either at the root or the tip of the blade with zero consequence regarding a stall. Heck, it'd be more like a stall fence.

Can a mold be made using RenShape 460 Medium-High Density Modeling Board for casting carbon fiber? Your thoughts?

Thanks!

I had planned on designing a mold for a 2-part polyurethane foam but might as well go with carbon fiber if it's doable. I have zero experience in designing a mold so am asking for pointers.

The fan blade is based on a Cessna (NACA 2412) airfoil. It's chord is 39.9mm and height is 37.5mm. I'd originally thought I'd design the mold with the blade laying horizontally in the cavity, but since I'm putting a Sportsman STOL leading edge on it, there's no way I can think of to do it without having a parting line near the leading edge which is unacceptable (a parting line near the leading edge would encourage a stall of the blade). So, I'll likely have to design the mold with the leading and trailing edges of the blade/airfoil vertical. I don't mind the draft, tapered wings are everywhere. Why not in my fan? That way the parting line could be either at the root or the tip of the blade with zero consequence regarding a stall. Heck, it'd be more like a stall fence.

Can a mold be made using RenShape 460 Medium-High Density Modeling Board for casting carbon fiber? Your thoughts?

Thanks!