- Joined

- Jul 22, 2013

- Messages

- 130

I recently replaced the igaging scales on my minimill with glass scales. Using touchdro and the results are fantastic. Should have done it years ago. But what to do with the old scales. Ah, I can put them on my Lathe. A Logan 820. But it's 10x24 and the longest scale from my minimill is only 18. Should I just live with the limits to the travel? And then I remembered.

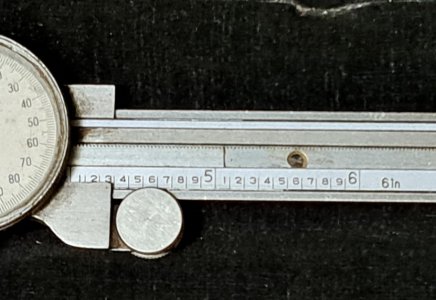

I cut down the 24" scale to fit the x axis of the mill. And I still have the cutoff piece. Would it be possible to rejoin the two and get a functional scale for the lathe?

Well, some small holes drilled, two wire pins and some jb weld later. Tada, back to one piece. But does it still work? With a little judicious filing and sanding I remounted the read head. Hooked it back up to the iGaging readout and started running it back and forth over the join. And can you believe it? I can't find a bobble, jump, skip, or lost position at all. It's not mounted to the lathe yet. And I intend to put the join at the tailstock end since 99% of my work is up front. So I won't hit that spot much. But I can keep the full travel of my lathe and get dro.

Now, I don't know if the fact that this works speaks to my 'phenomenal' work putting the scale back together or the cr@ppy nature of igaging scales and the bizarre processing they do to smooth out the bumps. But I suspect that if I hooked this up to a touchdro I might see something different. Hmmm, now where did I put that old DIY touchdro board........

I cut down the 24" scale to fit the x axis of the mill. And I still have the cutoff piece. Would it be possible to rejoin the two and get a functional scale for the lathe?

Well, some small holes drilled, two wire pins and some jb weld later. Tada, back to one piece. But does it still work? With a little judicious filing and sanding I remounted the read head. Hooked it back up to the iGaging readout and started running it back and forth over the join. And can you believe it? I can't find a bobble, jump, skip, or lost position at all. It's not mounted to the lathe yet. And I intend to put the join at the tailstock end since 99% of my work is up front. So I won't hit that spot much. But I can keep the full travel of my lathe and get dro.

Now, I don't know if the fact that this works speaks to my 'phenomenal' work putting the scale back together or the cr@ppy nature of igaging scales and the bizarre processing they do to smooth out the bumps. But I suspect that if I hooked this up to a touchdro I might see something different. Hmmm, now where did I put that old DIY touchdro board........

Last edited: