-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

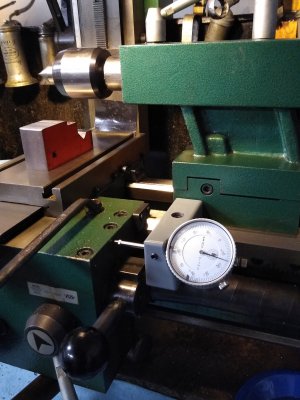

Dial Indicator Carriage Stop

- Thread starter BROCKWOOD

- Start date

C- Bag, I know it's impolite to answer a question with a question. It's just cold rolled steel, like the twin sitting on the carriage in the 2nd pic that is awaiting a micrometer install. I painted it Winter Gray after rolling the edges on a sander. So, my question: What is UHMW?

- Joined

- Feb 9, 2017

- Messages

- 5,547

No problem. I didn’t get it had been painted. It looked so perfect I was wondering what it was made out of. UHMW stands for ultra high molecular weight plastic. It’s this crazy dense plastic that’s used for all kinds of stuff. We used to use it in heavy conveyors for chain slides replacing 1”square key stock. You never had to replace the UHMW where you’d have to replace the key stock every 3-4 seasons.

I use the chunks of UHMW around the shop for all kinds of stuff, but never for a DI mount. And in looking at your I thought why not? Now I’m not so sure about using it as a stop, but for a mount where it’s just holding the DI I‘m pretty sure it would be ok.

I use the chunks of UHMW around the shop for all kinds of stuff, but never for a DI mount. And in looking at your I thought why not? Now I’m not so sure about using it as a stop, but for a mount where it’s just holding the DI I‘m pretty sure it would be ok.

This is a combo lathe / mill. So, as needed, I'll chuck a vise or rotary table up on the carriage & mill out a small part. I knew I wanted a left & a right carriage stop. Stefan G had mentioned that a dial indicator on the left side just messed up the face of the indicator because of hot chips landing on it. So, he put his on the right side.

Had to turn the blocks 45 degrees for the 'V'. Wanted to see which angle would put the dial at eye level & given my table / lathe height that also turned out to be 45 degrees. Dial diameter just happened to be just under my 2" facing mill size, so, I went for it.

For the micrometer stop I'm making for left of carriage - well, it's back to making a tool to make a tool. Mine is an 8" 4 jaw chuck & I need a spider for it in order to finish out this stop. Had to order up a piece of 8" 6160, but am moving forward with a smaller piece.

Had to turn the blocks 45 degrees for the 'V'. Wanted to see which angle would put the dial at eye level & given my table / lathe height that also turned out to be 45 degrees. Dial diameter just happened to be just under my 2" facing mill size, so, I went for it.

For the micrometer stop I'm making for left of carriage - well, it's back to making a tool to make a tool. Mine is an 8" 4 jaw chuck & I need a spider for it in order to finish out this stop. Had to order up a piece of 8" 6160, but am moving forward with a smaller piece.

- Joined

- Jan 2, 2014

- Messages

- 9,380