- Joined

- Dec 18, 2019

- Messages

- 7,333

I don't want to clutter up @Pescadora's thread with my project, so I thought I would start one of my own. Been very attracted to parting with little trouble. Parting is great when your lathe is set up just so, but on occasion, weird stuff happens and parting becomes a horror show. This just recently happened, so I am ready to make something to mount on my G0752Z lathe. I like the idea of taking the compound out of the picture for this. It's also great to take out the need for adjusting all the degrees of freedom that contribute to a bad parting session. So taking the plunge. This first part of the thread is about the design, and measuring the correct offset of the blade.

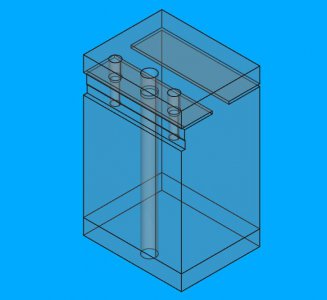

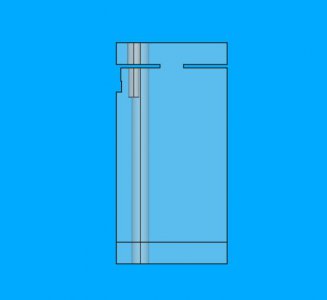

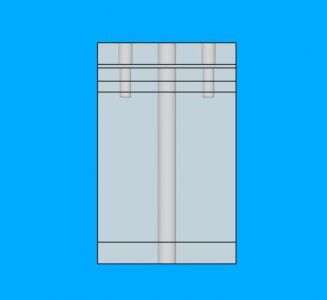

@mikey has suggested some basic design elements that one should adhere to, namely a double opposed slit. Honestly, I'm on the fence on the need for it, but think for this pass, I will go with his recommendation. I can always change the design and make a different one! I have modeled the parting tool holder for a 1/2" blade. If people want, I can post the FreeCAD file for this. I used spreadsheet based design for this, so it should be pretty easy to adapt to your own lathe. Of course, you will have to know FreeCAD, but if I could learn it, you can too!

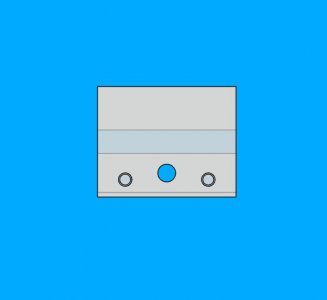

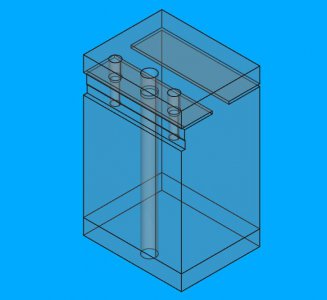

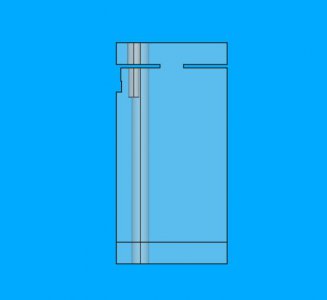

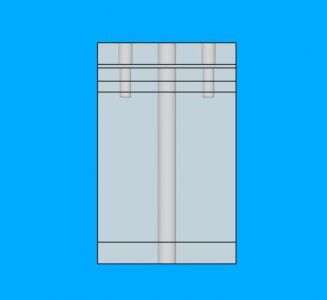

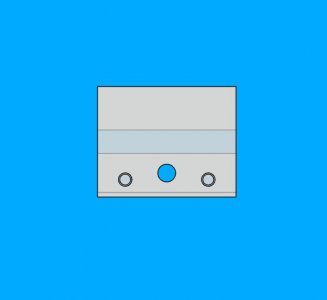

The holder is made from a piece of 2 x 2.5 x 4 inch 6061, because I have a chunk of metal that is 2x2.5x6. I am using an M8 for the hold down to the cross-slide and two M6 screws as additional blade clamps. The M8 hole is spaced at 11mm from the edge, which is about midpoint of the thickness available to drill in my cross-slide. Here are a couple of views of what I have so far. No technical drawings with full dimensions yet, but all of the dimensions are in the model. Kind of goofed up with the bottom, it used to have a mounting flange, but I took it out. This is one single block.

I am going to have fun drilling the M8 through hole as my drill bits are not long enough. Any tips on flipping the piece to drill through? Any thoughts on design changes?

@mikey has suggested some basic design elements that one should adhere to, namely a double opposed slit. Honestly, I'm on the fence on the need for it, but think for this pass, I will go with his recommendation. I can always change the design and make a different one! I have modeled the parting tool holder for a 1/2" blade. If people want, I can post the FreeCAD file for this. I used spreadsheet based design for this, so it should be pretty easy to adapt to your own lathe. Of course, you will have to know FreeCAD, but if I could learn it, you can too!

The holder is made from a piece of 2 x 2.5 x 4 inch 6061, because I have a chunk of metal that is 2x2.5x6. I am using an M8 for the hold down to the cross-slide and two M6 screws as additional blade clamps. The M8 hole is spaced at 11mm from the edge, which is about midpoint of the thickness available to drill in my cross-slide. Here are a couple of views of what I have so far. No technical drawings with full dimensions yet, but all of the dimensions are in the model. Kind of goofed up with the bottom, it used to have a mounting flange, but I took it out. This is one single block.

I am going to have fun drilling the M8 through hole as my drill bits are not long enough. Any tips on flipping the piece to drill through? Any thoughts on design changes?