- Joined

- Oct 17, 2018

- Messages

- 966

I have a dial indicator with 1" of travel I'd like to use as a tailstock depth gauge on my Atlas Craftsman 101.07403 lathe. I've looked around for reference but it seems no one has done this, probably because there isn't and easy way to attach the dial since the tailstock as all round. All of what I found in my research was on lathes that had a flat top on the tailstock.

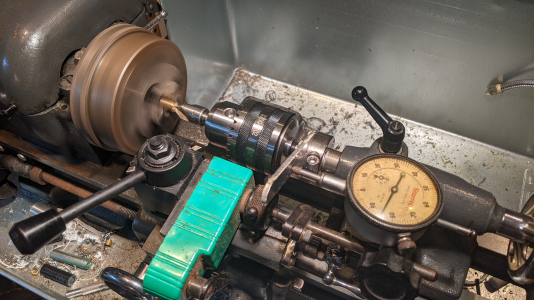

Here are some pictures showing how I'd like to mount it:

I thought I might tap the hole that was originally for lube and make some sort of mounting bracket for the indicator. I would then make a sleeve for the ram that the indicator needle touched (not shown here). The other option is for some sort of press-fit post.

Has anyone ever done something like this to this specific machine? I'd like to see images and get any thoughts and comments on what you did, how you did and if you are happy with it.

Thanks!

UPDATE: See post #9 for my solution.

Here are some pictures showing how I'd like to mount it:

I thought I might tap the hole that was originally for lube and make some sort of mounting bracket for the indicator. I would then make a sleeve for the ram that the indicator needle touched (not shown here). The other option is for some sort of press-fit post.

Has anyone ever done something like this to this specific machine? I'd like to see images and get any thoughts and comments on what you did, how you did and if you are happy with it.

Thanks!

UPDATE: See post #9 for my solution.

Last edited: