- Joined

- Mar 3, 2013

- Messages

- 1,448

I purchased a Delta Model 28-380 Wood/Metal bandsaw from Craigs List in 2016. It has the art-deco cast iron base. It appears to have originally come from an industrial plant (paper tag on motor says "good motor for bandsaw building 50"). The previous owner kept it in a dirt floor basement. I suspect it had been sitting

unused for at least 10 years before I purchased it.

One of the cast iron pieces of the base was broken but I did find a reasonably priced replacement on eBay. I didn't take any before pictures. I have it dissembled and I've started cleaning it up. The major pieces will be de-rusted using electrolysis.

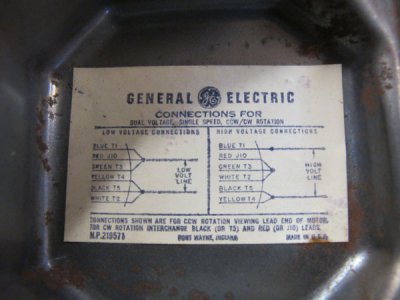

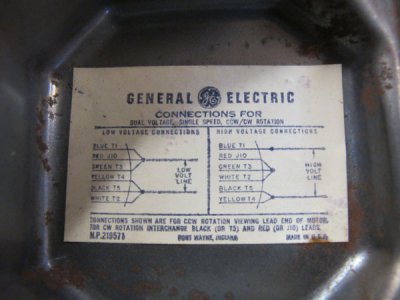

The motor was rather rusty and desperately needed new bearings but did run. This was cleaned

up with an angle grinder, primed, painted, new bearings and a new starter cap. Although the old

starter cap worked it was leaking so I ordered a new one. The bearings were replaced with double

seal 6203 bearings. I have included pictures of the motor tag and wiring diagram in case someone

needs this info in the future. The original capacitor was marked 110V 60CY 400-480 MFD.

It was 3 3/8" long and 2" in diameter. My replacement is electrically the same but physically

smaller.

Below is the first item out of the electrolysis tank. This was after about 5 days.

One day was lost because the sacrificial electrode was so dirty it was no longer

doing anything. The sacrificial electrode really needs to be cleaned every day

for efficient operation, it get rather gross. Cleaning is just scraping with a putty

knife.

This item is one end of the cast iron base. After coming out of the tank I rinsed

it with clean water and a quick once over with some Dawn dish detergent and a

Scotch-brite kitchen sponge.

unused for at least 10 years before I purchased it.

One of the cast iron pieces of the base was broken but I did find a reasonably priced replacement on eBay. I didn't take any before pictures. I have it dissembled and I've started cleaning it up. The major pieces will be de-rusted using electrolysis.

The motor was rather rusty and desperately needed new bearings but did run. This was cleaned

up with an angle grinder, primed, painted, new bearings and a new starter cap. Although the old

starter cap worked it was leaking so I ordered a new one. The bearings were replaced with double

seal 6203 bearings. I have included pictures of the motor tag and wiring diagram in case someone

needs this info in the future. The original capacitor was marked 110V 60CY 400-480 MFD.

It was 3 3/8" long and 2" in diameter. My replacement is electrically the same but physically

smaller.

Below is the first item out of the electrolysis tank. This was after about 5 days.

One day was lost because the sacrificial electrode was so dirty it was no longer

doing anything. The sacrificial electrode really needs to be cleaned every day

for efficient operation, it get rather gross. Cleaning is just scraping with a putty

knife.

This item is one end of the cast iron base. After coming out of the tank I rinsed

it with clean water and a quick once over with some Dawn dish detergent and a

Scotch-brite kitchen sponge.