-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Delta 11" 25-100 Lathe Parts

- Thread starter Kroll

- Start date

kroll.

I have a delta 11 in lathe--if you need pics, I will be glad to help. The best source for info on the lathe might be this URL: https://store.lathes.co.uk/print/md311. There is a military operations lathe manual, but is of little value for parts pics. The gear teeth I think you are referring to do not have very deep teeth when new.

homestead

I have a delta 11 in lathe--if you need pics, I will be glad to help. The best source for info on the lathe might be this URL: https://store.lathes.co.uk/print/md311. There is a military operations lathe manual, but is of little value for parts pics. The gear teeth I think you are referring to do not have very deep teeth when new.

homestead

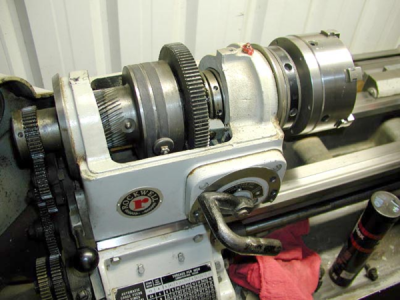

Thanks Homestead,I will be ordering myself manual from the link.I hate taking apart something without a manual.Here's couple pics of my lathe,the previous owner was very nice person who told me what was wrong with the lathe before I went to look at it.So there is more good about this lathe than bad,just have to overcome this gear problem.Adding another pic of the bad part that I need to replace,any ideals

Last edited:

4

4GSR

Forum Guest

Register Today

Kroll,

There has been several threads on this same subject posted on the Rockwell Lathe group on Yahoo. Pretty much what it comes to is you have to machine off all of the existing gear teeth, down to a certain diameter. Then buy a stock gear from Boston Gear or Martin, bore it out for a shrink fit to the turned diameter on the pulley. Don't need much, about .0005" to .001" interference. You have to do likewise to the mating gear, too. The teeth count for both gears change, too. I just notice, you have a thread going on the Rockwell lathe group for this. Anyways, this is just about the only way it's going to get fixed other than building from scratch a new part.. There is nobody out there providing repair parts for these lathes nowadays.

There has been several threads on this same subject posted on the Rockwell Lathe group on Yahoo. Pretty much what it comes to is you have to machine off all of the existing gear teeth, down to a certain diameter. Then buy a stock gear from Boston Gear or Martin, bore it out for a shrink fit to the turned diameter on the pulley. Don't need much, about .0005" to .001" interference. You have to do likewise to the mating gear, too. The teeth count for both gears change, too. I just notice, you have a thread going on the Rockwell lathe group for this. Anyways, this is just about the only way it's going to get fixed other than building from scratch a new part.. There is nobody out there providing repair parts for these lathes nowadays.

Thanks Ken,I do have one running over at Yahoo group.I was told by several that there is alot of Rockwell lathe owners there.I read also your post on getting a 14" Rockwell which I bet is very nice.I was clueless on how to repair something like this but couple guys come up with a game plan and I sent the parts off to gentleman who want to give it a try making the repairs.This is one lathe that I should have givin little more though before buying,but with the help I may be able to have a 1964 11" Delta/Rockwell lathe.But I'm not out of the woods yet so my fingers are cross

Well heck Ken I see your post here,fantastic

Well heck Ken I see your post here,fantastic