- Joined

- Jul 9, 2018

- Messages

- 314

I am getting ready to cut some aluminum as a 1st cut ever.

So I have a few questions:

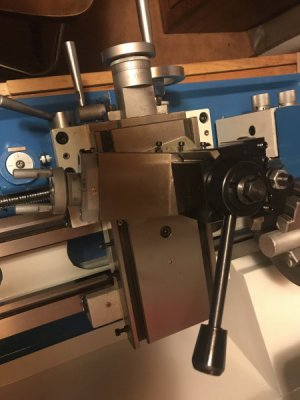

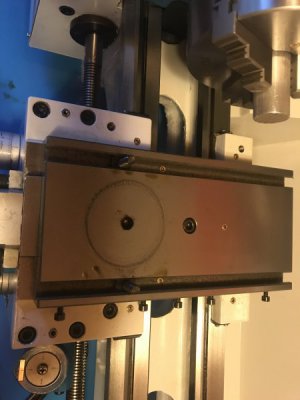

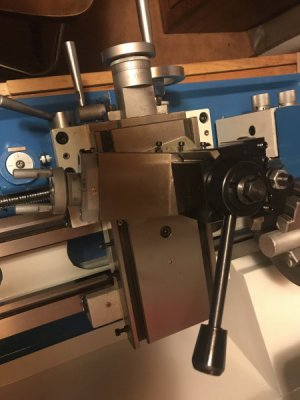

Why does my compound slide have grooves and a big area that my cross slide and tool rest will never be able to travel, due to a hole and plug on the compound that mates to the cross slide base?

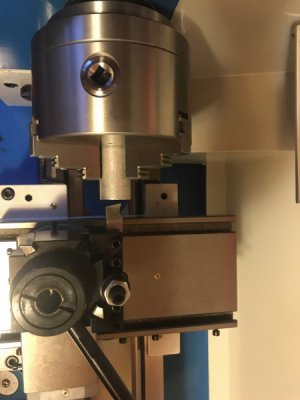

What sort of angles should my QCTP and cross slide be at for a facing cut?

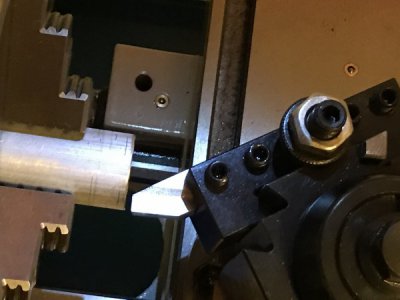

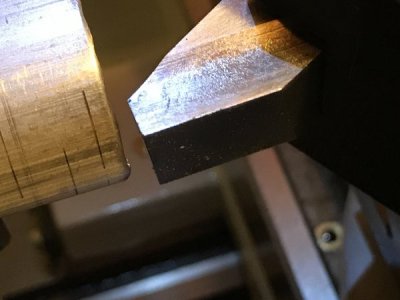

I have a selection of Hss tools and not sure on orientation and choice of tool?

I mounted one up and took a guess at position but not sure?

Let me know what you think.

Thanks for the guidance!!

So I have a few questions:

Why does my compound slide have grooves and a big area that my cross slide and tool rest will never be able to travel, due to a hole and plug on the compound that mates to the cross slide base?

What sort of angles should my QCTP and cross slide be at for a facing cut?

I have a selection of Hss tools and not sure on orientation and choice of tool?

I mounted one up and took a guess at position but not sure?

Let me know what you think.

Thanks for the guidance!!