- Joined

- May 14, 2013

- Messages

- 104

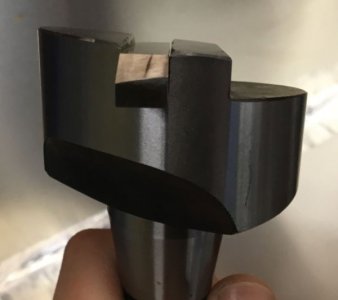

A lovely present was in the mail when I got home - an R8 flycutter! Got it cleaned up, ground the HSS blank, and took some test cuts. I definitely need a power feed on the X-axis, haha!

Some questions!!

- The chips/dust produced - what does that indicate?

- When running this past about 200rpm, the entire machine goes into harmonic vibrations until about 700rpm? - normal for a flycutter on a small machine? (I haven't bolted this to the counter yet)

- Other input/suggestions?

Wooo

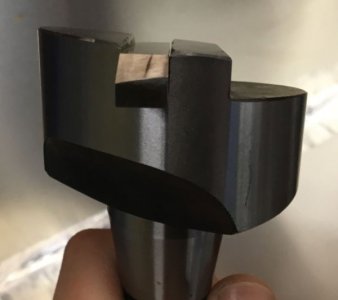

Result of two passes

- Center of cutter diameter was in line with the left side of this round stock.

- First pass, very light (2-3 thou). Second pass, 5-6 thou.

- Very slow manual feed rate. (uh.... 5 thou a second? Maybe a bit less?)

- It took about 5-10m per pass (my kingdom for a power feed!)

- About 200rpm spindle speed (guessing - I have no RPM meter yet)

The center of the blank has some ridging, but I suspect that's because I didn't get past the rough hacksawn surface. The outer edge is perfectly flat.

During the cut, there was a kind of flat chip being produced and pushed forward, and the rest is just that dust you see.

Cutter grind

Based off this post's guidance: how-do-i-sharpen-hss-blanks-for-fly-cutting

I ground it in, then used a 'normal' diamond card to hone it as best I know how. After watching the Tom's Techniques video on flycutting, I have some more grinding knowledge to apply for next time!

Some questions!!

- The chips/dust produced - what does that indicate?

- When running this past about 200rpm, the entire machine goes into harmonic vibrations until about 700rpm? - normal for a flycutter on a small machine? (I haven't bolted this to the counter yet)

- Other input/suggestions?

Wooo

Result of two passes

- Center of cutter diameter was in line with the left side of this round stock.

- First pass, very light (2-3 thou). Second pass, 5-6 thou.

- Very slow manual feed rate. (uh.... 5 thou a second? Maybe a bit less?)

- It took about 5-10m per pass (my kingdom for a power feed!)

- About 200rpm spindle speed (guessing - I have no RPM meter yet)

The center of the blank has some ridging, but I suspect that's because I didn't get past the rough hacksawn surface. The outer edge is perfectly flat.

During the cut, there was a kind of flat chip being produced and pushed forward, and the rest is just that dust you see.

Cutter grind

Based off this post's guidance: how-do-i-sharpen-hss-blanks-for-fly-cutting

I ground it in, then used a 'normal' diamond card to hone it as best I know how. After watching the Tom's Techniques video on flycutting, I have some more grinding knowledge to apply for next time!