- Joined

- Mar 28, 2023

- Messages

- 23

I have a Sherline lathe and a Taig ER16 spindle adapter that threads onto the spindle of my lathe. However, because the differences of the Sherline and Taig spindle noses, the threads in the adapter don't start at the base, causing it to only engage one or two on the Sherline spindle:

The base of the adapter sits on the shoulder of the spindle, which is the reference surface for the Sherline.

My goal is to shorten this end so more threads engage. I was able to find one other person that has talked about doing this, but I don't have the same tooling as they do.

My issue is that I want to ensure this surface is concentric to the collet's bore, otherwise I assume the collet and therefore the stock it's holding could be pointing at an angle to the bore of the lathe.

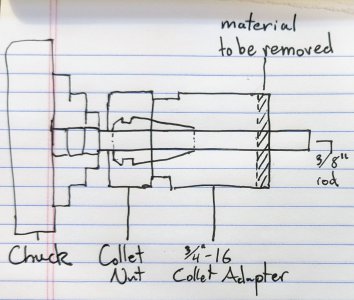

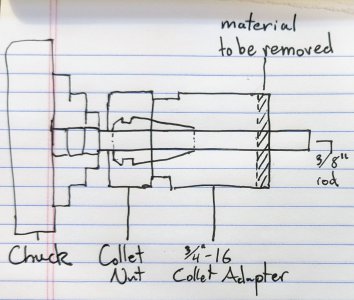

This is my current plan, and what I'd like input on: I want to turn a piece of steel to 3/8" (the largest collet I have), mount the adapter onto that rod backwards using a 3/8" collet, then face down the end.

Questions:

A few things:

The base of the adapter sits on the shoulder of the spindle, which is the reference surface for the Sherline.

My goal is to shorten this end so more threads engage. I was able to find one other person that has talked about doing this, but I don't have the same tooling as they do.

My issue is that I want to ensure this surface is concentric to the collet's bore, otherwise I assume the collet and therefore the stock it's holding could be pointing at an angle to the bore of the lathe.

This is my current plan, and what I'd like input on: I want to turn a piece of steel to 3/8" (the largest collet I have), mount the adapter onto that rod backwards using a 3/8" collet, then face down the end.

Questions:

- Would this maintain concentricity, at least to a reasonable degree?

- Should I use a center in the end of the stock? (Would it even it matter that much?)

- I was planning on using a center to remove most of the material, but create the final shape without a center so that only the chuck is influencing the stock. Then shorten the adapter without a center as well.

- For my particular lathe, I do know that when I turn using a tailstock center I get less taper.

- Now that I'm thinking about it, it seems like using a center the whole way may be best?

A few things:

- I have Techniks collets, so not the cheapest ones out there. I feel like I can count on their accuracy in this instance.

- I feel like the "true" way to do this would be to hold the adapter backwards in the 4-jaw and dial it in with an indicator on its internal ER taper, but I don't think that's viable with what I have