- Joined

- May 26, 2015

- Messages

- 875

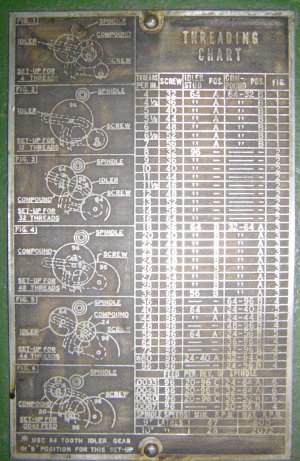

Just finished restoring a Crafty 12x42. Been suggested that my lathe was mfg between 1939-1942. I looked thru various literature for what is recommended for just general daily use other than threading. Anyone have a suggestion for banjo gear selection for A-B-C-D locations. My lead screw has a 64 tooth and is slow as molasses.