- Joined

- Apr 28, 2018

- Messages

- 77

Hi,

While looking and trying to learn about T&C Grinders, I came across one of the old vintage Craftsman drill sharpeners we have all seen.

I have one of the original square Drill Doctors that work up to 3/4", and it works pretty well, but sometimes, I do not get exactly what I want?

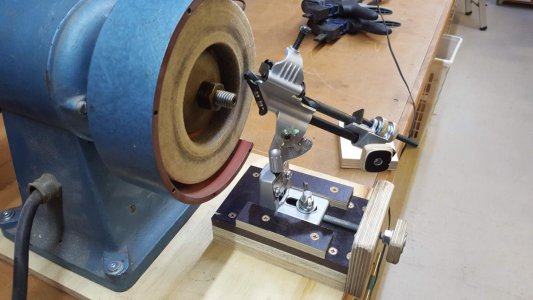

Thought the Craftsman might give me more tweeking power with some bits and I have plenty of old bench grinders collected over the years.

Just wondering if anyone has used these in there shop and what kind of set up you used??????????????

While looking and trying to learn about T&C Grinders, I came across one of the old vintage Craftsman drill sharpeners we have all seen.

I have one of the original square Drill Doctors that work up to 3/4", and it works pretty well, but sometimes, I do not get exactly what I want?

Thought the Craftsman might give me more tweeking power with some bits and I have plenty of old bench grinders collected over the years.

Just wondering if anyone has used these in there shop and what kind of set up you used??????????????