Without adding a bunch of needless detail, I recently scored a great deal on an old Craftsman 101.07380 12x24" lathe in really nice condition. There were only a few minor issues that were easily repaired, except for the traverse gear case assembly, which was completely missing! The 10F-11 Carriage Gear Case from later models of this lathe (equipped with the power cross slide feature) seems to be relatively common and according to my research, shares the gears and shaft of the earlier 9_11 case. The two gear cases are in no way compatible, however. Hole spacing is different and angular orientation of the holes is different.

I ran across a listing on eBay for a new gear case machined from aluminum bar stock but it would be about $130 shipped, so I wasn't much interested in a replacement part that cost a little less than half what I gave for the entire lathe and tooling. I did manage to find a 10F-11 assembly on eBay that had a broken case for $50 shipped, and I jumped on it to scavenge the gears and shaft.

Knowing that Clausing does maintain a parts inventory for many of these early lathes, I sent them an email. Took several days to get a response and when I did, it was bad news. Erin at Clausing's customer service department informed me that this part had been discontinued many years ago and they had none in stock. She also very graciously attached a large pdf file of the original blueprint for this part!!!

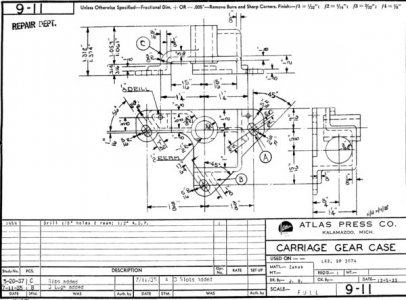

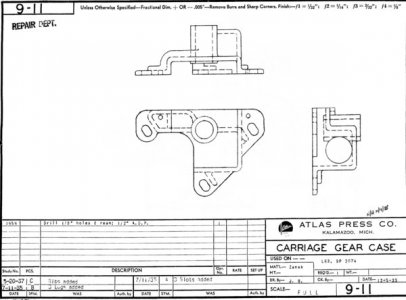

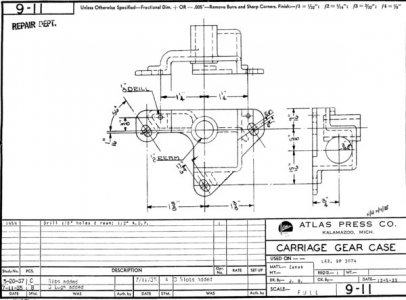

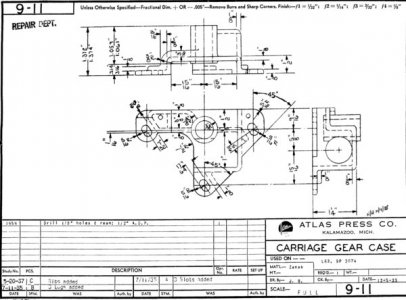

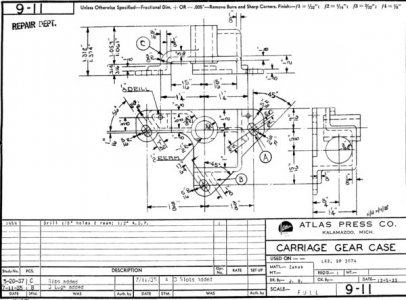

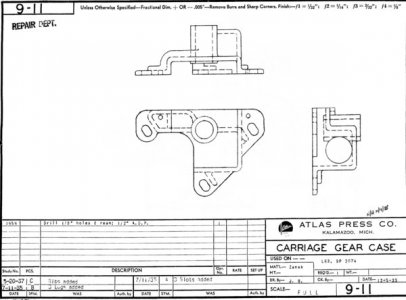

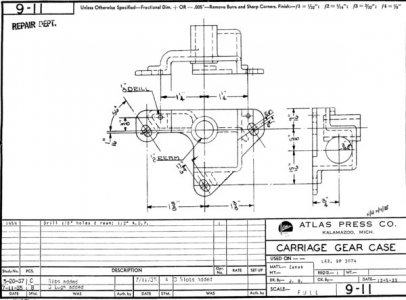

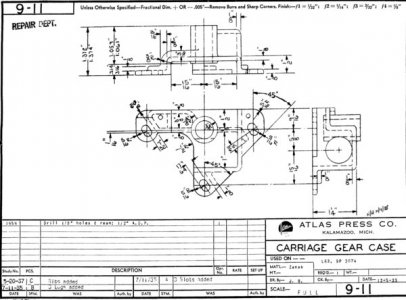

Having this blueprint, any relatively competent machinist should be able to make this rare part from aluminum bar stock and get their lathe back in action. As the original print was both physically dirty and very cluttered, I took the liberty of converting the file to jpg and then breaking it down into multiple prints. The first is the original print as rotated into alignment and then the dirt, specks, and other photocopying "noise" cleaned up a bit. Photo 2 (nodim) has no dimensions whatsoever, so you can actually "see" the gear case, should you be in my shoes and have nothing to go by. Photo 3 (holedim) has only the hole size and location dimensions. Photo 4 (surfdim) has only the surface dimensions. Should any of my work on photos 2, 3, and 4 prove suspect, simply refer to photo 1 for clarification. I could have easily flubbed something up during the modifications.

I'm hopeful this minor piece of work may help someone out on down the road. I'll be starting one of these for my lathe as soon as I finish a couple of small projects and can focus on it!

I ran across a listing on eBay for a new gear case machined from aluminum bar stock but it would be about $130 shipped, so I wasn't much interested in a replacement part that cost a little less than half what I gave for the entire lathe and tooling. I did manage to find a 10F-11 assembly on eBay that had a broken case for $50 shipped, and I jumped on it to scavenge the gears and shaft.

Knowing that Clausing does maintain a parts inventory for many of these early lathes, I sent them an email. Took several days to get a response and when I did, it was bad news. Erin at Clausing's customer service department informed me that this part had been discontinued many years ago and they had none in stock. She also very graciously attached a large pdf file of the original blueprint for this part!!!

Having this blueprint, any relatively competent machinist should be able to make this rare part from aluminum bar stock and get their lathe back in action. As the original print was both physically dirty and very cluttered, I took the liberty of converting the file to jpg and then breaking it down into multiple prints. The first is the original print as rotated into alignment and then the dirt, specks, and other photocopying "noise" cleaned up a bit. Photo 2 (nodim) has no dimensions whatsoever, so you can actually "see" the gear case, should you be in my shoes and have nothing to go by. Photo 3 (holedim) has only the hole size and location dimensions. Photo 4 (surfdim) has only the surface dimensions. Should any of my work on photos 2, 3, and 4 prove suspect, simply refer to photo 1 for clarification. I could have easily flubbed something up during the modifications.

I'm hopeful this minor piece of work may help someone out on down the road. I'll be starting one of these for my lathe as soon as I finish a couple of small projects and can focus on it!

Last edited: