- Joined

- Aug 6, 2020

- Messages

- 35

With the lathe now all disassembled, it's time to start the rebuild. That means starting with a base. Like most of these lathes, this on spent most of its time mounted to a 2 x 12 from the lumber yard on a top of a home made cabinet. I hope to do a little better and address some of the shortcomings of this lathe.

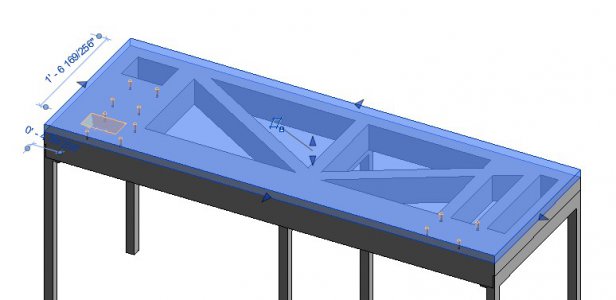

I've sketched up concept that is still getting refined. It will be a UHPC (ultra high performance concrete) frame, topped with either a granite or quartz countertop remnant. The concrete frame will provide most of the rigidity and the countertop will give the lathe a nice flat surface that even has the possibility to be used for some layout. The coefficient of thermal expansion is very similar for the cast iron @ 10.8, reinforced concrete @ 9.8, granite @ ~8 . Quartz is higher at 12 with the plastic resins. But man made quartz is more consistently flat. The specifications for quartz are a flatness of 0.063" over a slab that is 36" x 48". Not a surface plate, but a darn flat surface by any standard. And if you measure most of these, they usually exceed this standard. Specifications for granite is supposed to be 1/8" over 10 ft, or 0.0125" per ft. But I think the natural variation of this makes this more difficult and the hand polishing done at the edges, I'm sure puts in more dips.

The concrete frame will act as a torsion tube and beam below the lathe bed. and inserts will be cast in for bolting everything down. The concrete will be cast on the back of the granite, but not permanently secured. any holes will just be thru holes and the granite will be leveled on the base with silicone adhesive and pins.. So if I want to redecorate or modify the top later, it could be removed.

The top will have a hole and sump cut below the headstock to collect all the fluids and swarf below the top. If I want to clean the gears and headstock, everything will just drain down and not run all over the bench. I may rout in a recess in the top around the lathe to collect cutting fluids separately. (Or just steal a cookie sheet from the kitchen.)

Still tinkering with what I'm going to do with the legs. This will be in the basement, so I may just use the foundation wall and some brackets as the support for the back edge and a couple of simple support legs on the front. Not sure yet if I want to go that direction. I have a good spot and doubt I'll ever want to push the thing around.

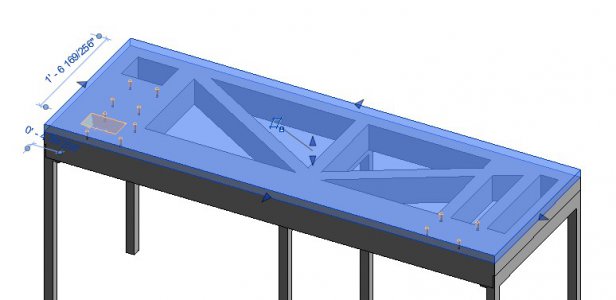

I've sketched up concept that is still getting refined. It will be a UHPC (ultra high performance concrete) frame, topped with either a granite or quartz countertop remnant. The concrete frame will provide most of the rigidity and the countertop will give the lathe a nice flat surface that even has the possibility to be used for some layout. The coefficient of thermal expansion is very similar for the cast iron @ 10.8, reinforced concrete @ 9.8, granite @ ~8 . Quartz is higher at 12 with the plastic resins. But man made quartz is more consistently flat. The specifications for quartz are a flatness of 0.063" over a slab that is 36" x 48". Not a surface plate, but a darn flat surface by any standard. And if you measure most of these, they usually exceed this standard. Specifications for granite is supposed to be 1/8" over 10 ft, or 0.0125" per ft. But I think the natural variation of this makes this more difficult and the hand polishing done at the edges, I'm sure puts in more dips.

The concrete frame will act as a torsion tube and beam below the lathe bed. and inserts will be cast in for bolting everything down. The concrete will be cast on the back of the granite, but not permanently secured. any holes will just be thru holes and the granite will be leveled on the base with silicone adhesive and pins.. So if I want to redecorate or modify the top later, it could be removed.

The top will have a hole and sump cut below the headstock to collect all the fluids and swarf below the top. If I want to clean the gears and headstock, everything will just drain down and not run all over the bench. I may rout in a recess in the top around the lathe to collect cutting fluids separately. (Or just steal a cookie sheet from the kitchen.)

Still tinkering with what I'm going to do with the legs. This will be in the basement, so I may just use the foundation wall and some brackets as the support for the back edge and a couple of simple support legs on the front. Not sure yet if I want to go that direction. I have a good spot and doubt I'll ever want to push the thing around.