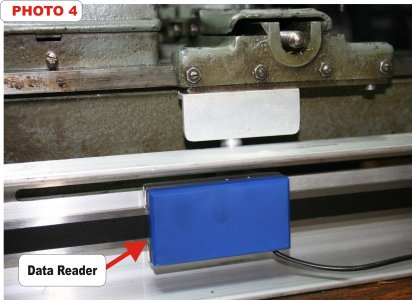

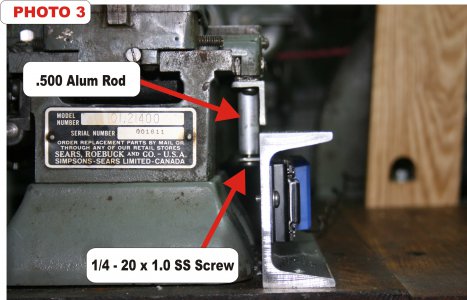

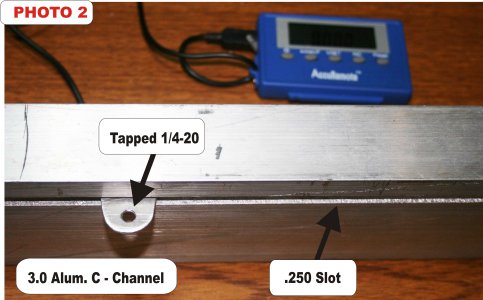

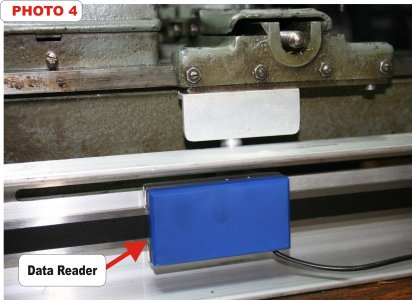

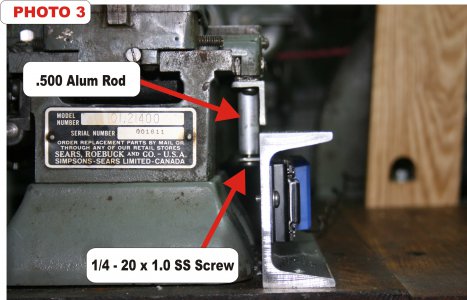

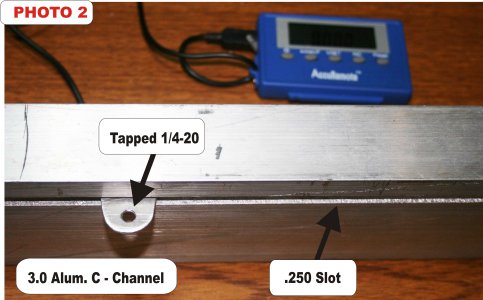

I just added a Grizzly SS 24" Digital remote read out to my new, Craftsman 101.2140 lathe. PHOTO 1 - I made a small bracket and mounted the the back of the data reader with the screws that came with the reader. PHOTO 2 - I used a 3" C-Channel to mount and protect the data reader and track from oil and chips. Milled a .250 slot for the bracket to extend out. PHOTO 3 - I added a bracket from the carriage bearing plate with longer screws. The .500 rod is mounted to the bracket with a 10-24 x .750 counter sunk screw. The 1/4-20 screw just rides in a .246 hole in the .500 rod. (this is the 1st part I made in the lathe) PHOTO 4 - I mounted the bracket to the back of the carriage to keep the data reader farther away from the chip area. It glides along with the carriage and you cant tell it's there other then the new digital read out.

I still need to make a chip pan and deflector when I can get access to a press break to remove and control the chips. Will be added a digital read out on the tail stock and carriage next.

This is my 1st project post and I'm a little rusty after 8 years of retirement. I feels so good to get back into designing and building again.

Craig

I still need to make a chip pan and deflector when I can get access to a press break to remove and control the chips. Will be added a digital read out on the tail stock and carriage next.

This is my 1st project post and I'm a little rusty after 8 years of retirement. I feels so good to get back into designing and building again.

Craig